- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you Need to Know About Pet Food Extruder Machine

Everything you Need to Know About Pet Food Extruder Machine

2024-04-19 14:35:33Introduction to Pet Food Extruder Machine Technology

Pet food extruder machines are pivotal in the production of high-quality pet food products. These specialized machines are designed to efficiently process various ingredients into nutritious and palatable pet food formulations. Utilizing advanced technology, pet food extruder machines play a crucial role in shaping, cooking, and forming pet food products, ensuring consistency and quality throughout the manufacturing process.

Pet food extruder machines are equipped with components such as a barrel, screw, die, and cutter, which work in tandem to transform raw ingredients into finished pet food products. The extrusion process involves the application of heat, pressure, and mechanical force to mix, cook, and shape the ingredients into a desired form, such as kibble, treats, or snacks. This versatile processing technique allows for precise control over product texture, density, and nutritional content, catering to the specific dietary needs and preferences of different pets.

Types of Pet Food Extruder Machines Available

Types of Pet Food Extruder Machines Available

There are several types of pet food extruder machines available on the market, each designed to meet specific production requirements and preferences of pet food manufacturers. One common type is single-screw extruders, which feature a single rotating screw housed within a barrel. These extruders are suitable for processing a wide range of ingredients and are known for their simplicity and reliability in operation.

Another type is twin-screw extruders, which utilize two intermeshing screws to convey, mix, and cook the ingredients. Twin-screw extruders offer greater flexibility and control over the extrusion process, allowing for precise adjustment of parameters such as temperature, pressure, and residence time. They are often preferred for processing complex formulations and specialty pet food products.

Additionally, there are specialized extruder machines designed for specific applications, such as cold extrusion for producing raw or freeze-dried pet food products, and high-shear extrusion for creating textured or high-meat content pet foods. These machines incorporate unique features and configurations to accommodate the unique requirements of different pet food formulations and processing conditions.

Components and Working Principle of Pet Food Extruders

Components and Working Principle of Pet Food Extruders

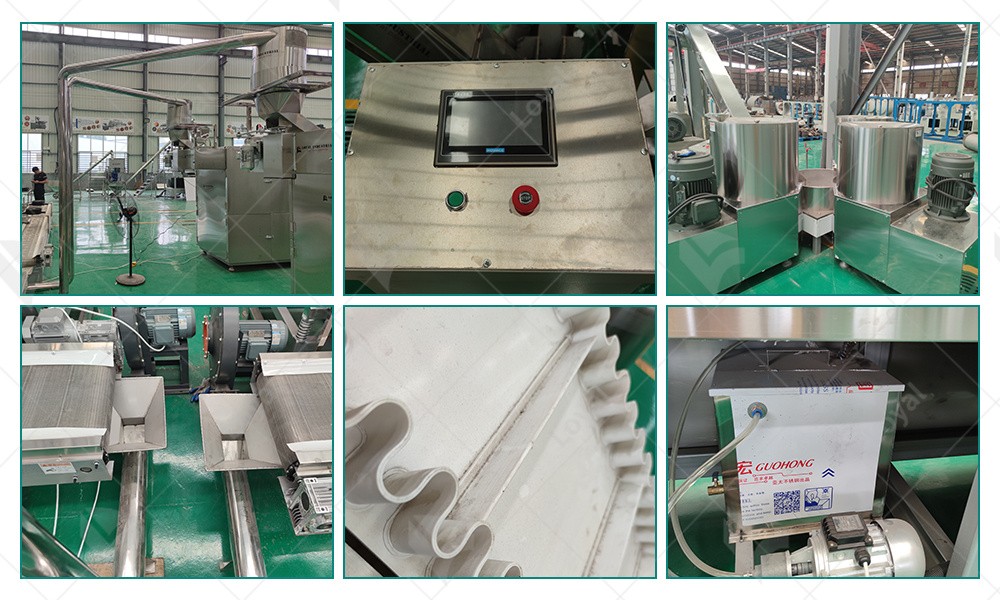

Pet food extruder machines are intricate systems composed of several key components that work together to produce high-quality pet food products. The primary components of a pet food extruder include the feed hopper, screw conveyor, barrel, die, and cutting mechanism.

The working principle of a pet food extruder involves the mechanical and thermal processing of raw ingredients to transform them into a uniform, easily digestible product. The process begins with the introduction of raw materials into the feed hopper, where they are conveyed by the screw conveyor towards the barrel of the extruder.

Inside the barrel, the raw ingredients are subjected to a combination of mechanical shear forces and high temperature generated by the friction of the rotating screws. This heat and pressure cause the ingredients to undergo cooking, gelatinization, and expansion, resulting in the formation of a semi-cooked dough-like mass.

As the dough-like mass moves through the barrel, it is forced through a shaping die at the end of the extruder. The die determines the final shape and size of the extruded pet food product. Upon exiting the die, the extrudate is cut into uniform pieces by a cutting mechanism before being cooled and dried to achieve the desired texture and moisture content.

Pet food extruders typically operate in a continuous manner, with precise control over parameters such as temperature, pressure, screw speed, and moisture content to ensure consistent product quality and characteristics.

Benefits of Using Pet Food Extruder Machines

Pet food extruder machines offer a range of benefits that make them indispensable in the pet food processing industry. One of the primary advantages is the versatility of extrusion technology, which allows for the production of a wide variety of pet food products, including dry kibble, semi-moist treats, and textured snacks.

Additionally, pet food extruders enable efficient and uniform mixing of ingredients, ensuring consistent nutritional content and flavor in every batch. The cooking process in the extruder eliminates harmful bacteria and pathogens, enhancing the safety and shelf life of the final product.

Furthermore, pet food extruder machines are highly customizable, allowing manufacturers to tailor product attributes such as shape, size, density, and texture to meet the specific preferences and dietary requirements of different pet species and breeds.

Another significant benefit of using pet food extruders is the cost-effectiveness of the extrusion process. By optimizing ingredient utilization, reducing waste, and minimizing the need for additional processing steps, extrusion technology helps manufacturers achieve higher production yields and lower overall production costs.

Overall, the utilization of pet food extruder machines results in improved product quality, production efficiency, and profitability for pet food manufacturers, making them essential equipment in the pet food processing industry.

Comparison of Different Brands of Pet Food Extruder Machines

When selecting a pet food extruder machine, several factors must be taken into account to ensure optimal performance and efficiency. Let's compare the machines from LOYAL and Coperion across various aspects:

|

Aspect |

LOYAL Pet Food Extruder |

Coperion Pet Food Extruder |

|

Capacity |

Higher capacity models available to accommodate large-scale production needs. |

Offers a range of capacities suitable for small to large-scale operations. |

|

Versatility |

Capable of processing a wide range of ingredients and formulations, including dry and wet materials. |

Provides versatile processing options for various pet food recipes and formulations. |

|

Efficiency |

Incorporates advanced technologies to maximize energy efficiency and minimize downtime. |

Known for high operational efficiency and reliability, reducing production costs. |

|

Hygienic Design |

Features a hygienic design with easy-to-clean components and sanitation protocols. |

Designed with sanitation in mind, ensuring compliance with industry hygiene standards. |

|

Durability |

Constructed from durable materials to withstand the rigors of continuous operation. |

Engineered for longevity and robust performance, minimizing maintenance requirements. |

|

Customization Options |

Offers customization options to tailor the machine to specific production requirements and preferences. |

Provides customizable features and configurations to meet unique processing needs. |

Applications of Pet Food Extruder Machines in the Industry

1. Dry Pet Food Production: Pet food extruders are utilized to produce dry kibble, pellets, and biscuits for dogs, cats, and other pets. The extrusion process ensures uniform cooking and shaping of ingredients, resulting in consistent product quality and texture.

2. Semi-Moist Pet Treats: Extruders are employed to manufacture semi-moist pet treats such as chewy snacks and jerky. The precise control over temperature and moisture during extrusion allows for the production of soft and flavorful treats with extended shelf life.

3. Functional Pet Foods: Pet food extruders enable the incorporation of functional ingredients such as vitamins, minerals, and supplements into pet food formulations. This facilitates the production of specialized diets tailored to meet specific nutritional needs or address health concerns in pets.

4. Novelty Pet Food Products: Extruders are used to create innovative pet food products, including shaped treats, textured foods, and interactive feeding solutions. Manufacturers can experiment with different ingredients and shapes to cater to evolving consumer preferences and trends.

Maintenance and Cleaning Tips for Pet Food Extruders

Regular maintenance routines should include inspecting all components of the extruder, such as screws, barrels, and die plates, for signs of wear and tear. Any worn or damaged parts should be promptly replaced to prevent operational issues and maintain product quality.

Cleaning procedures for pet food extruders typically involve disassembling the machine and thoroughly removing any remaining food particles, oils, or residues. It's crucial to follow manufacturer-recommended cleaning protocols and use appropriate cleaning agents to avoid damaging sensitive components.

In addition to routine maintenance and cleaning, operators should pay attention to lubrication requirements for the moving parts of the extruder. Proper lubrication helps reduce friction and wear, ensuring smooth operation and preventing breakdowns.

Regularly calibrating the extruder to maintain consistent product quality is also important. This involves adjusting operating parameters such as temperature, pressure, and screw speed to achieve the desired extrusion outcomes.

Furthermore, implementing a preventive maintenance schedule can help identify potential issues before they escalate into costly repairs or production downtime. This includes scheduling regular inspections, lubrication, and cleaning sessions based on the manufacturer's recommendations and machine usage.

Adopting proper handling and storage practices for pet food ingredients and additives can also contribute to the overall cleanliness and performance of the extruder. Ensuring that raw materials are free from contaminants and properly stored in clean, dry environments helps prevent contamination and maintains product integrity.

Regular training and education for machine operators on proper maintenance and cleaning procedures are essential to ensure compliance with industry standards and maximize the efficiency of pet food extruder machines.

Innovations and Trends in Pet Food Extruder Technology

The pet food industry is continuously evolving, driven by consumer demand for high-quality, nutritious pet food products. As a result, manufacturers are constantly innovating and introducing new technologies to improve the efficiency, versatility, and sustainability of pet food extruder machines.

One of the notable trends in pet food extruder technology is the integration of advanced controls and automation systems. These systems allow for precise monitoring and adjustment of extrusion parameters in real-time, resulting in greater consistency and product quality.

Another emerging trend is the development of multifunctional extruders capable of producing a wide range of pet food products, including kibble, treats, and textured proteins, using a single machine. This versatility allows manufacturers to streamline production processes and adapt to changing market demands more effectively.

Additionally, there is growing interest in sustainable manufacturing practices within the pet food industry, driving innovation in extruder design and materials. Manufacturers are exploring alternative energy sources, such as solar and biomass, and incorporating eco-friendly materials into extruder construction to reduce environmental impact.

Furthermore, advancements in material science and engineering have led to the development of novel extrusion technologies, such as cold extrusion and high-moisture extrusion, which offer unique advantages in terms of product texture, nutritional retention, and processing efficiency.

Overall, the future of pet food extruder technology is characterized by a focus on sustainability, efficiency, and product innovation, driven by evolving consumer preferences and industry regulations. By embracing these trends and investing in cutting-edge technology, manufacturers can stay ahead of the curve and meet the growing demand for high-quality pet food products.

Future Outlook for Pet Food Extruder Machine Development

One key area of development is the integration of IoT (Internet of Things) and AI (Artificial Intelligence) capabilities into pet food extruder machines. These technologies will enable machines to gather and analyze data in real-time, allowing for more precise control over the extrusion process. IoT sensors can monitor parameters such as temperature, pressure, and moisture content, while AI algorithms can optimize processing parameters to enhance efficiency and product quality.

There is a growing emphasis on sustainability in the development of pet food extruder machines. Manufacturers are exploring eco-friendly materials and energy-efficient designs to minimize environmental impact. This includes the use of renewable energy sources, such as solar or wind power, to operate extruder machines, as well as the incorporation of recyclable components and packaging materials.

Another trend in pet food extruder machine development is the customization of equipment to meet the specific needs of different pet food producers. Manufacturers are offering modular designs and flexible configurations that allow for easy adaptation to varying production requirements. This includes the ability to process a wide range of ingredients, from traditional grains and meats to alternative proteins and novel ingredients.

Additionally, there is ongoing research into novel processing techniques and ingredient formulations that can further enhance the nutritional quality and palatability of pet food products. This includes the use of advanced cooking and shaping technologies to create textures and shapes that mimic natural prey, as well as the incorporation of functional ingredients that support pet health and wellness.

In conclusion, the future of pet food extruder machine development is characterized by innovation, sustainability, and customization. By leveraging emerging technologies, optimizing process efficiency, and prioritizing environmental responsibility, manufacturers are poised to meet the evolving demands of the pet food industry while ensuring the health and happiness of pets worldwide.

FAQs: Frequently asked questions about Pet Food Extruder Machine

1. What is a pet food extruder machine, and how does it work?

A pet food extruder machine is a specialized piece of equipment used in the production of pet food. It works by using a combination of heat, pressure, and mechanical force to process raw ingredients into a uniform and digestible pet food product. The extrusion process involves forcing the mixture through a die under high pressure, resulting in the expansion and cooking of the ingredients.

2. What are the advantages of using a pet food extruder machine?

Pet food extruder machines offer several benefits, including efficient processing of ingredients, uniform product quality, versatility in producing different shapes and sizes of pet food, and the ability to control the nutritional content of the final product. Additionally, extrusion technology can improve the digestibility and palatability of pet food, leading to better overall health outcomes for pets.

3. What types of pet food can be produced using a pet food extruder machine?

Pet food extruder machines are capable of producing a wide range of pet food products, including dry kibble, semi-moist treats, and textured snacks. These machines can process various ingredients, such as grains, meats, vegetables, and additives, to create customized formulations tailored to the nutritional needs and preferences of different pets.

4. How do I choose the right pet food extruder machine for my production needs?

When selecting a pet food extruder machine, it's essential to consider factors such as production capacity, extrusion technology, equipment durability, ease of maintenance, and compatibility with your specific ingredients and recipes. Consulting with industry experts and conducting thorough research can help you make an informed decision based on your unique requirements.

5. What maintenance and cleaning procedures are required for pet food extruder machines?

Regular maintenance and cleaning are crucial for ensuring the optimal performance and longevity of pet food extruder machines. This includes routine inspections, lubrication of moving parts, and thorough cleaning of components to prevent buildup of residue or contaminants. Following manufacturer guidelines and implementing a preventive maintenance schedule can help minimize downtime and maximize productivity.

References

1. Food and Agriculture Organization of the United Nations (FAO): https://www.fao.org/home/en/

2. American Society of Agricultural and Biological Engineers (ASABE): https://www.asabe.org/

3. The Aquaculture Engineering Society (AES): https://www.aesweb.org/

4. European Aquaculture Society (EAS): https://www.aquaeas.eu/

5. International Aquafeed Magazine:https://www.international-aquafeed.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines