- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> Everything you need to know about cookies machine In 2024

Everything you need to know about cookies machine In 2024

2024-04-26 12:00:03Introduction

In the dynamic landscape of the food industry, cookies machines play a pivotal role in streamlining the production process and meeting the ever-growing demand for cookies worldwide. These sophisticated machines are integral to industrial food production, offering efficiency, precision, and consistency in the manufacturing of a variety of cookies. From traditional favorites to innovative creations, cookies machines enable manufacturers to produce large quantities of high-quality cookies to satisfy consumer preferences and market demands.

Cookies machines encompass a diverse range of equipment, each designed for specific functions within the cookie production process. From dough mixing to shaping, baking, and packaging, these machines automate and optimize each step, ensuring uniformity and adherence to quality standards. As we delve deeper into the intricacies of cookies machines, it becomes evident that they are not merely tools of production but essential assets that drive innovation, efficiency, and growth in the food industry.

Types of Cookies Machines

Cookies machines come in various types, each tailored to specific production needs and capabilities. One common type is the rotary moulder, which shapes dough into uniform cookies by passing it through rotating molds. This machine is ideal for producing round or cylindrical cookies with consistent size and shape. Another type is the wire-cut machine, which extrudes dough through a nozzle and cuts it into individual cookies using a wire or blade. This versatile machine can produce a wide range of cookie shapes and sizes, making it popular among manufacturers seeking flexibility in product offerings.

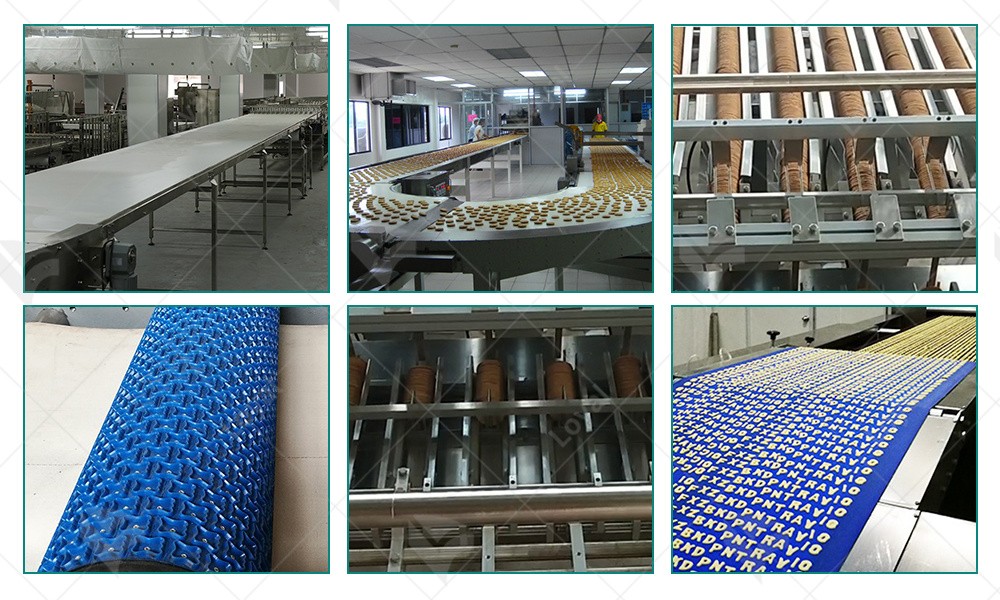

Moreover, depositor machines are widely used for depositing dough onto baking trays in precise portions, allowing for efficient production of cookies with intricate designs or fillings. Meanwhile, tunnel ovens provide controlled baking environments, ensuring even heat distribution and optimal baking results. Additionally, cooling conveyors are essential for rapidly cooling freshly baked cookies before packaging, preserving their texture and quality. By understanding the different types of cookies machines and their functionalities, manufacturers can select the most suitable equipment to meet their production requirements and achieve desired product specifications.

Technological Advancements in Cookies Machine for 2024

As we step into 2024, the technological landscape for cookies machines is evolving at a rapid pace. Innovations are not just enhancing the efficiency and output of these machines but also improving the quality of the cookies produced, reducing environmental impact, and streamlining the production process. Here's a look at some of the key technological advancements that are shaping the future of cookie production:

1. Automation and Robotics: The level of automation in cookies machines is increasing, with robotics being used to perform tasks such as dough handling, shaping, and even quality control. This not only increases the speed and precision of the process but also reduces the potential for human error.

2. Internet of Things (IoT): IoT technology is being integrated into cookies machines to enable real-time monitoring and data collection. This allows for better process control, predictive maintenance, and optimization of machine performance.

3. Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms are being used to analyze the data collected by IoT devices and make intelligent decisions about machine operation. This can lead to improved product quality, reduced waste, and increased efficiency.

4. Energy-Efficient Technologies: With a focus on sustainability, new energy-efficient technologies are being developed for cookies machines. This includes more efficient ovens, heat recovery systems, and the use of renewable energy sources where possible.

5. Advanced Material Science: The use of advanced materials in the construction of cookies machines can improve durability, reduce wear and tear, and lower maintenance costs. Additionally, some materials can improve the quality of the cookies produced by providing better heat conduction or more uniform baking.

6. 3D Printing: While still in its early stages for cookie production, 3D printing technology has the potential to revolutionize the way cookies are shaped and decorated. This could lead to more intricate designs and a wider variety of cookie shapes and styles.

7. Augmented Reality (AR): AR technology is being used for training and maintenance of cookies machines. By overlaying digital information onto the physical machine, operators can receive real-time guidance on machine operation and maintenance tasks, improving efficiency and reducing downtime.

8. Sustainability Features: New cookies machines are being designed with sustainability in mind. This includes features such as waste reduction systems, water recycling, and the use of eco-friendly packaging materials.

9. Customization and Flexibility: Advances in technology are allowing cookies machines to be more customizable and flexible, enabling them to produce a wider variety of cookie types and flavors. This can help manufacturers cater to changing consumer preferences and market trends.

10. Traceability and Transparency: With increasing consumer demand for transparency in the food production process, cookies machines are being equipped with traceability features. This allows manufacturers to track ingredients, monitor the production process, and provide information to consumers about the origin and quality of their cookies.

These technological advancements are not just making cookies machines more efficient and productive; they are also helping to improve the quality of the cookies produced, reduce the environmental impact of cookie production, and meet the changing needs and expectations of consumers. As technology continues to evolve, we can expect to see even more innovation in the field of cookie production, further enhancing the capabilities of cookies machines.

Working Principles and Processes

Understanding the working principles and processes of cookies machines is essential for optimizing production efficiency and ensuring product quality. These machines typically follow a series of steps to transform raw ingredients into finished cookies, employing advanced technology and precision engineering along the way.

Firstly, the dough preparation stage involves mixing ingredients such as flour, sugar, fats, and flavorings to create a homogeneous dough. This mixture is then fed into the cookies machine, where it undergoes shaping and forming according to the machine's design. Rotary molders use rotating molds to shape the dough into consistent shapes, while wire-cut machines extrude dough through a nozzle and cut it into individual portions.

Next, the shaped dough is transferred to baking trays or conveyor belts and transported to the oven for baking. Tunnel ovens provide controlled heat and airflow to ensure uniform baking and achieve desired cookie textures and colors. Once baked, the cookies move to cooling conveyors, where they are rapidly cooled to room temperature to halt the baking process and prevent overcooking.

Throughout these processes, cookies machines incorporate automation, sensors, and controls to monitor and adjust parameters such as dough consistency, shaping, baking time, and temperature. This automation ensures precision and consistency in cookie production, minimizing variations and defects.

By mastering the working principles and processes of cookies machines, manufacturers can optimize production workflows, improve product quality, and meet the demands of discerning consumers in the competitive food industry landscape.

Key Components and Features

Cookies machines comprise several key components and features that contribute to their efficiency, reliability, and performance in the production process.

One of the fundamental components of cookies machines is the dough feeder, which accurately feeds dough into the machine for further processing. It ensures a consistent flow of dough, preventing jams and interruptions in production. Additionally, extruders play a crucial role in shaping the dough into desired forms. These components utilize pressure and precision to extrude dough through molds or nozzles, creating uniform shapes and sizes.

Cutting mechanisms are another essential feature of cookies machines, responsible for dividing the dough into individual portions or shapes. Whether using rotary cutters, wire-cut blades, or stamping molds, these mechanisms ensure precise cutting and consistent results. Ovens are integral to the baking process, providing controlled heat and airflow to achieve optimal baking conditions. Modern ovens may incorporate features such as programmable temperature settings, multiple heating zones, and steam injection capabilities for enhanced baking performance.

Furthermore, cooling systems are essential for quickly cooling baked cookies to prevent overcooking and maintain product quality. Conveyor belts or cooling racks facilitate the efficient transfer of cookies from the oven to the cooling area, where ambient air or refrigeration systems expedite the cooling process.

In addition to these components, cookies machines may feature advanced technologies such as PLC (Programmable Logic Controller) systems, touchscreen interfaces, and remote monitoring capabilities. These features enhance operational control, facilitate troubleshooting, and improve overall efficiency in cookie production.

Overall, the integration of key components and features in cookies machines ensures smooth and reliable operation, allowing manufacturers to meet production targets while delivering high-quality cookies to consumers.

Market Trends and Outlook

The market for cookies machines is witnessing a dynamic shift driven by several discernible trends that not only shape industry dynamics but also catalyze innovation and redefine market landscapes. One of the most prominent trends in recent years is the escalating demand for customization and product diversification. As consumers increasingly seek unique and innovative cookie flavors, shapes, and textures, manufacturers are compelled to invest in cookies machines capable of producing a diverse array of products that cater to evolving consumer preferences.

Furthermore, sustainability and environmental consciousness have emerged as pivotal factors influencing the design and manufacturing of cookies machines. Manufacturers are progressively integrating eco-friendly materials, energy-efficient technologies, and waste reduction measures into their machine designs to minimize environmental footprint and align with stringent regulatory standards. This shift towards sustainability underscores a broader industry commitment towards responsible production practices and eco-conscious manufacturing processes.

Moreover, the advent of automation and digitalization has revolutionized the cookies machine market, ushering in a new era of efficiency, productivity, and quality optimization. Integrated sensors, IoT connectivity, and AI algorithms empower manufacturers with real-time monitoring capabilities, predictive maintenance insights, and data-driven decision-making tools, thereby enhancing operational efficiency, reducing downtime, and ensuring consistent product quality across production cycles.

Additionally, the globalization of consumer markets and evolving consumer preferences have spurred expansion opportunities for cookies machine manufacturers, particularly in emerging economies. Rising disposable incomes, urbanization trends, and evolving consumer lifestyles have fueled the demand for packaged cookies and convenience foods in regions with burgeoning food processing industries, presenting lucrative opportunities for manufacturers to capitalize on.

Looking ahead, the outlook for the cookies machine market remains optimistic, with sustained growth, innovation, and market expansion anticipated. Manufacturers that adeptly navigate evolving consumer trends, embrace sustainability initiatives, and leverage cutting-edge technologies will be well-positioned to seize growth opportunities, foster market competitiveness, and sustain long-term success in the dynamic cookies machine market.

Regulations and Compliance for Cookies Machine Operation

Regulations and compliance are crucial for the operation of a cookies machine, ensuring that the production process is safe, efficient, and environmentally responsible. Adhering to global standards and local laws is a legal necessity and a testament to a company's commitment to quality and safety.

Global standards, such as those set by the ISO, along with local and national laws, govern various aspects of food machinery operation, including food safety, worker protection, and environmental impact. Compliance with these regulations is essential to prevent contamination, ensure worker safety, and minimize the environmental footprint of the production process.

Food safety regulations, like the HACCP principles, are designed to identify and control potential hazards in the production process. Meanwhile, machine safety compliance involves equipping the cookies machine with guards, emergency stop mechanisms, and safety interlocks to protect workers from accidents.

Environmental regulations often dictate the power sources and emissions standards for food machinery. Energy-efficient designs and the use of renewable energy sources are increasingly important in meeting these standards and reducing the carbon footprint of the production process.

Attaining certifications like ISO 22000 for food safety management or ISO 14001 for environmental management systems can demonstrate a company's commitment to regulatory compliance. Regular audits by regulatory bodies and third-party organizations verify that these standards are being met and maintained.

The role of technology in aiding compliance cannot be overstated. Modern cookies machines often feature automated monitoring systems that detect potential safety or contamination issues, and digital records that provide the traceability necessary for regulatory inspections.

Continuous education and training are vital for staying informed about the latest regulatory changes and industry best practices. This ongoing commitment to learning and improvement ensures that the operation of a cookies machine remains up to date with the latest laws and standards.

In essence, regulatory compliance is not just a legal obligation but a commitment to excellence in food production. It is a framework that guides the safe, efficient, and responsible operation of cookies machines, allowing the industry to thrive while protecting public health and the environment.

Conclusion

The cookies machine is a cornerstone of the cookie industry, driving innovation and efficiency in the production of one of the world's most beloved treats. As we look to the future, the role of these machines becomes even more critical. They are not just tools for cookie making; they are a symbol of the industry's commitment to quality, sustainability, and meeting the diverse preferences of consumers worldwide.

The advancements in technology are paving the way for a new era of cookie production. From automation and AI to sustainability features and customization options, the cookies machine of the future is set to be more efficient, more versatile, and more environmentally friendly than ever before. As the industry continues to evolve, these machines will play a crucial role in shaping the future of cookie production, ensuring that the joy of cookies can be enjoyed by generations to come.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines