- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> High-Efficiency Fully Automatic Fish Feed Machinery: Streamlined Pellet Manufacturing Techniques

High-Efficiency Fully Automatic Fish Feed Machinery: Streamlined Pellet Manufacturing Techniques

2024-10-28 16:33:41Overview of fish feed production

In the world of aquaculture, the demand for high-quality fish feed has surged significantly, driven by the increasing global appetite for seafood. As a result, the fish feed production industry is witnessing a shift towards more efficient and automated solutions. One of the most vital components of this evolution is the fish feed pellet machine. This machinery not only enhances production efficiency but also ensures that the nutritional needs of fish are met in a consistent manner.

{图}

Importance of high-efficiency machinery in aquaculture

According to Dr. John Smith, a leading expert in aquaculture technology, "The integration of automated systems in fish feed production allows for better control over the manufacturing process, resulting in higher quality feed and reduced waste." This sentiment reflects a growing recognition within the industry that adopting fully automatic equipment is essential for meeting the increasing demand while maintaining sustainability.

Understanding Fish Feed Production Lines

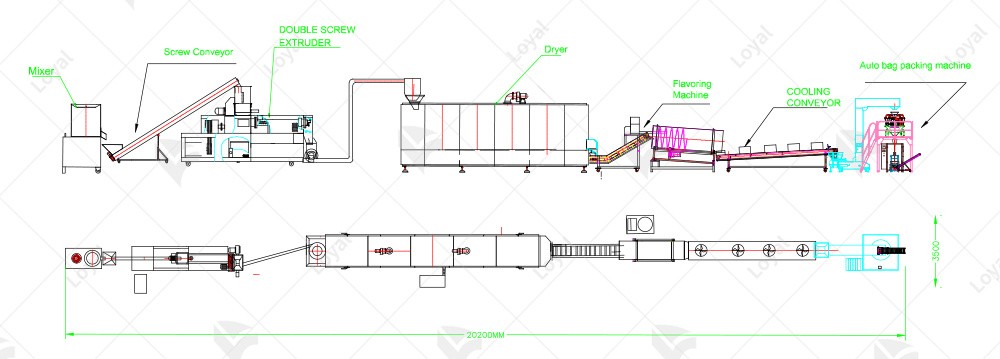

The fish feed production line is a complex assembly of interconnected machines designed to create high-quality fish feed pellets. Each component plays a crucial role in the manufacturing process, ensuring that the final product meets both nutritional and quality standards.

Components of a fish feed production line

|

Mixers |

These machines are used to blend various ingredients such as grains, proteins, fats, vitamins, and minerals into a homogeneous mixture. High-quality mixers ensure that all components are evenly distributed, resulting in a balanced feed. |

|

|

Extruders |

Extruders are critical in shaping the feed into the desired form, whether it's pellets, flakes, or crumbles. They apply pressure and heat to the mixture, forcing it through a die with specific shapes and sizes. The resulting feed is dense, durable, and easy to digest. |

|

|

Coaters |

Coaters are used to apply a layer of fat or other nutrients to the feed. This not only enhances the palatability of the feed but also helps in preserving it by creating a moisture barrier. |

|

|

Pelletizers |

Pelletizers are specifically designed to produce pellets, which are a popular form of fish feed due to their ease of handling and storage. These machines use a combination of pressure and cutting blades to shape the mixture into uniform, cylindrical pellets. |

|

|

Dryers and Coolers |

After extrusion and shaping, the feed needs to be dried and cooled to prevent mold and bacteria growth. Dryers use heated air to remove moisture, while coolers rapidly reduce the temperature of the feed to prevent it from becoming sticky or losing quality. |

|

Key characteristics of modern fish feed machinery

Modern fish feed machinery is characterized by several advanced features that enhance productivity and efficiency:

Automation: Fully automatic systems reduce the need for manual labor and minimize human error, allowing for a more streamlined production process. This automation includes everything from ingredient handling to packaging.

Energy Efficiency: With growing concerns about environmental sustainability, many modern machines are designed to consume less energy while maintaining high output levels. This not only lowers operational costs but also aligns with global sustainability goals.

Precision Control: Advanced sensors and control systems allow for precise monitoring of the entire production line. This ensures that every batch of fish feed pellets meets quality standards.

Modularity: Many contemporary fish feed production lines are modular, allowing manufacturers to easily scale up or adapt their production capabilities based on demand.

By understanding the components and characteristics of a fish feed production line, stakeholders in the aquaculture industry can make informed decisions about investing in high-efficiency fully automatic machinery that meets their production needs.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://loyalfoodmachine.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines