- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Discover The Secret To Perfect Nutrition Bars Making Machine: Nutrition Bars Making MachineRecipes

Discover The Secret To Perfect Nutrition Bars Making Machine: Nutrition Bars Making MachineRecipes

2025-05-16 17:48:13If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

Introduction – The Future of Nutrition Bars Production

The demand for healthy, convenient snacks like nutrition bars is skyrocketing! Whether it’s protein bars, granola bars, or keto-friendly options, consumers want high-quality, delicious options they can trust. But how do manufacturers keep up with this demand while maintaining consistency and efficiency? The answer lies in a high-speed Nutrition Bars Making Machine – the game-changer for modern snack production.

A nutrition bars production line isn’t just about speed; it’s about precision. Traditional methods can be slow, inconsistent, and labor-intensive, leading to wasted ingredients and higher costs. But with an advanced Nutrition Bars Process Line, you can automate mixing, shaping, cutting, and packaging—ensuring every bar meets the highest standards.

Why does this matter? Because today’s market rewards brands that deliver both quantity and quality. A top-tier Nutrition Bars Making Machine lets you produce thousands of bars per hour without sacrificing texture, taste, or structural integrity. Imagine scaling your business effortlessly, reducing waste, and boosting profits—all while keeping your product premium.

Whether you’re a startup launching your first nutrition bars production line or an established brand upgrading your Nutrition Bars Process Line, investing in the right machinery is the key to staying ahead. In the next sections, we’ll break down exactly how this innovative system works and why it’s a must-have for anyone serious about dominating the snack industry.

Stay tuned—because the future of nutrition bars production starts here!

How the High-Speed Nutrition Bar Making Machine Works (Simple & Powerful Process)

Ever wondered how your favorite nutrition bars are made so perfectly? The secret is in the Nutrition Bars Making Machine – a smart, automated system that turns raw ingredients into ready-to-eat bars in minutes! Let’s break down how this nutrition bars production line works, step by step:

Step 1: Smart Mixing – Perfect Blend Every Time

The process starts with a high-efficiency mixer that combines oats, nuts, proteins, sweeteners, and other ingredients evenly. Unlike manual mixing, this Nutrition Bars Process Line ensures no clumps or dry spots—just a smooth, consistent batter every time.

Step 2: Precision Forming – No More Crumbling Bars!

Next, the mixture moves into the forming stage, where the Nutrition Bars Making Machine presses it into the ideal thickness and shape. No more broken bars or uneven edges—just perfectly formed snacks, ready for cutting.

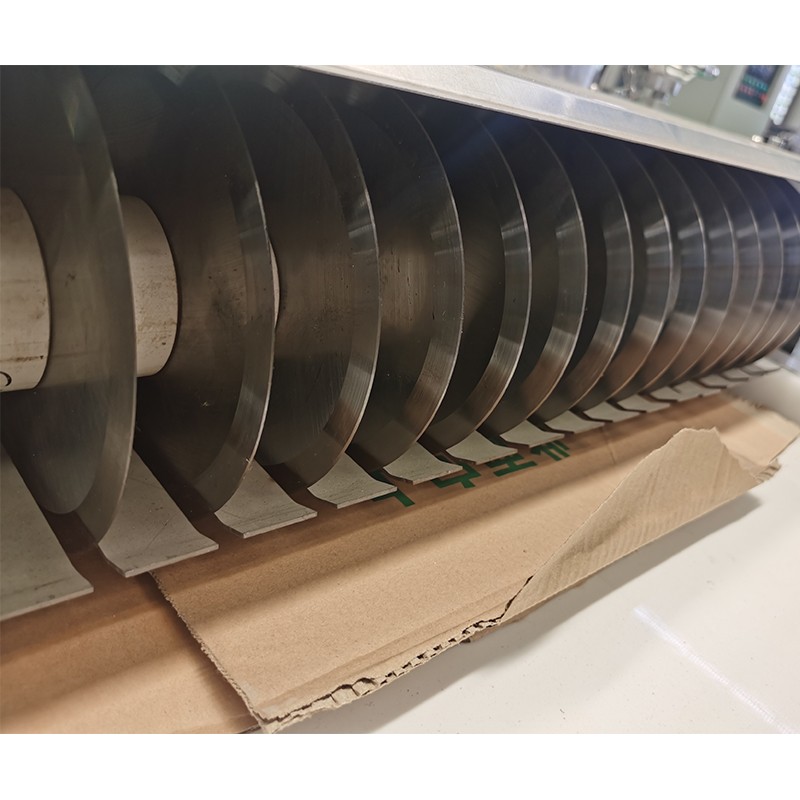

Step 3: Fast & Accurate Cutting

A high-speed cutter slices the bars into uniform sizes, whether you’re making mini snack bites or full-sized protein bars. This step in the nutrition bars production line guarantees every piece looks as good as it tastes.

Step 4: Cooling & Packaging – Ready for Market!

Finally, the bars cool quickly before being wrapped automatically. The Nutrition Bars Process Line can handle different packaging styles—flow wrap, pouch, or box—so your product looks professional and stays fresh longer.

Why This Process Wins?

✅ Faster than manual methods – Produce X bars per hour with no slowdowns

✅ Better consistency – No more uneven textures or broken bars

✅ Easy to customize – Adjust thickness, size, and ingredients for any recipe

This Nutrition Bars Making Machine isn’t just about speed—it’s about flawless production from start to finish. And the best part? It fits into any nutrition bars production line, whether you’re a small business or a large factory.

Flowchart Of The Nutrition Cereal Bars Production Process

Cereal Bar Mixer — screw conveyer— Twin-screw extruder —Sifter—Air conveyer —Flaking machine —Air conveyer — Multi-layer oven — Hoister — High Temperature Roaster Oven —Melting sugar machine —Sprayer sugar—Hoister —Roller — Air compressor— Hoister — Multi-layer oven— Cooling machine

SMALL NUTRITION BARS MAKING MACHINE LIST

|

NO. |

SMALL NUTRITION BARS MAKING MACHINE LIST |

|

1 |

Protein Bar Manufacturing Equipment |

|

2 |

Sugar Boiled Pot |

|

3 |

Mixing Machine |

|

4 |

Automatic Cereals Bar Cutting Machine |

|

5 |

Packing Machinery |

How to Nutrition Bars Making Production Line?

The Nutrition Bars Making Process Line is a professional line. At the same time , it can make peanut bars, protein bars and cereal bars. And it mainly used in corn flour, grain flour, potato flour and other grains. They as its main raw materials. And in it can also add raisins, dried cranberries and ground peanuts and other foods. The products can have rich taste. And they are deeply loved by consumers. It is all made of food grade 304 stainless steel. So it has advanced technology and superior performance. The PLC makes the operation very simple. The whole line only needs one person to complete the production. So, it is not only reduces labor costs, but also it is improves production efficiency.And it can provide a variety of comprehensive after-sales services to solve all worries for buyers.

Application of Nutrition Bars Making Machines

Nutrition Bars Making Machines is a very popular equipment on the market. It has more advantages than ordinary production lines. And it is suitable for making various bar-shaped biscuits. Such as protein bars, chocolate bars, nutrition bars, peanut bars and cereal bars. At the same time, it can manufacture almost all the hot-selling products on the market.

It main body and funnel are made of food grade stainless steel. Special molds and nozzles can meet the different needs of customer to produce food. It has different sizes. And it has install before leaving the factory. So it is more convenient for buyers to use it without installation. At the same time, it is simple to operate, ordinary workers can easily operate. And it is more practical. It is a high-quality equipment. And it is popular with buyers.

List Complete Of Energy Nutrition Bar Production Line

|

List Complete Of Energy Nutrition Bar Production Line |

|||

|

Energy Bar Machine Name |

Capacity |

|

|

|

1.Sugar Melting Pot |

100L |

|

|

|

200L |

|

||

|

2.Mixer |

3-8kg/Time |

|

|

|

12-20kg/Time |

|

||

|

3.Cereal Molding Machine |

150-200kg/H |

|

|

|

4.Cereal Bar Cutter |

50-100kg/H |

|

|

What are the advantages of Nutrition Bars Making Machines?

1.Nutrition Bars Process Line is mainly used for the food processing and molding produced in medium and large food industry, such as: Satsuma, Rice candy, Rice bar, Frozen rice candy, Sesame candy bar, Peanut brittle(peanut candy bar), Sunflower seeds candy bar, Coarse grains, Cereal bar and other molding and cutting.

2.Nutrition Bars production Line control the speed with the best frequency changer in China, according to different sizes, controlled by the PLC computer, simple to operate, easy to use, it is the ideal equipment to cut the block for the modern food industry.

3.We just need to know the capacity and the cutting size for final sesame candy or peanut brittle.We will provide the best project for our customers.

Why Choose This Advanced Nutrition Bars Production Line?

The snack industry is competitive, and only the most efficient producers come out on top. Here’s why upgrading to this high-performance Nutrition Bars Making Machine is the smartest decision for your business:

Unmatched Production Speed

Traditional methods limit how many bars you can make per hour. But with this automated nutrition bars production line, you can produce [X] bars per hour—that’s [X] times faster than manual processing! No more bottlenecks, just smooth, high-volume output to meet any demand spike.

Consistent, High-Quality Bars Every Time

Say goodbye to broken, uneven, or poorly mixed bars. This Nutrition Bars Process Line uses precision technology to ensure:

✔ Perfect texture – No crumbling or stickiness

✔ Even ingredient distribution – Every bite tastes the same

✔ Custom shapes & sizes – Stand out on shelves

Huge Cost Savings = Bigger Profits

Labor costs eating into your margins? This Nutrition Bars Making Machine slashes expenses by:

✔ Reducing manual work by up to 80%

✔ Minimizing ingredient waste with precise measurements

✔ Lowering energy use with efficient motors

Total Flexibility for Any Recipe

Whether you make:

• Protein bars

• Granola bars

• Keto-friendly snacks

• Vegan/gluten-free options

...this nutrition bars production line adapts in minutes! Change recipes, shapes, or packaging without expensive retooling.

Smart Tech for Easy Operation

Worried about complex machinery? This Nutrition Bars Process Line features:

• Touchscreen controls – Adjust settings with one tap

• Auto-cleaning mode – Saves hours of sanitation work

• Remote monitoring – Track production from your phone

Real Results: A Customer’s Success Story

"After installing this Nutrition Bars Making Machine, we tripled our output while cutting labor costs in half. Now we supply 5 major grocery chains!"

— [Founder, PowerBite Nutrition]

The Bottom Line

This isn’t just another machine—it’s your competitive edge. Faster production + premium quality + lower costs = unstoppable growth in the booming nutrition bar market.

Key Features of the Ultimate Nutrition Bars Process Line

When investing in a Nutrition Bars Making Machine, you need technology that delivers both performance and reliability. Our advanced nutrition bars production line comes packed with innovative features designed to maximize your output while maintaining exceptional quality. Let's explore what makes this system truly special.

First, the intelligent mixing system revolutionizes your ingredient preparation. Unlike traditional mixers, this Nutrition Bars Process Line features precision dosing that automatically measures each component to within 1% accuracy. The programmable memory stores up to 50 different recipes, allowing you to switch between product formulations with just one touch. After each batch, the self-cleaning function activates, reducing sanitation time by 70% and keeping your operation running smoothly.

The forming stage showcases the true power of this Nutrition Bars Making Machine. Our dual-layer pressing technology ensures perfect density throughout each bar, eliminating air pockets or weak spots. You can easily adjust thickness from 5mm for delicate snack bites up to 25mm for hearty protein bars. The special non-stick surfaces prevent ingredient buildup, maintaining consistent quality batch after batch without constant manual cleaning interruptions.

Cutting precision reaches new levels in this nutrition bars production line. The laser-guided cutting system delivers perfectly uniform portions every time, with adjustable sizes ranging from 25g mini-bites to 100g full-size bars. The vibration-free blades ensure clean cuts without crumbling, even for sticky or chunky formulations. This attention to detail means you'll dramatically reduce product waste while achieving professional-looking results.

Packaging integration sets this Nutrition Bars Process Line apart from conventional systems. The automated wrapping station handles everything from flow-wrapping individual bars to assembling multi-packs. Specialized sensors detect any imperfect seals, automatically rejecting substandard packages to maintain your quality standards. The system accommodates various packaging materials, including eco-friendly options, giving you flexibility to meet market demands.

Energy efficiency is built into every component of this Nutrition Bars Making Machine. The smart power management system reduces energy consumption by up to 40% compared to conventional models. When production pauses, the machine automatically enters low-power mode, then instantly resumes full operation when needed. These innovations not only lower your operating costs but also support sustainable manufacturing practices.

The user-friendly interface makes operating this nutrition bars production line surprisingly simple. The 15-inch color touchscreen displays real-time production data in an intuitive format. Operators can monitor output speed, track material usage, and receive maintenance alerts at a glance. Remote access capabilities allow managers to check production status from anywhere, ensuring complete oversight of your operation.

Safety features are integrated throughout the Nutrition Bars Process Line. Emergency stop buttons are strategically placed at all workstations, while protective shields automatically engage during high-speed operations. The machine's self-diagnostic system runs continuous checks, alerting technicians to potential issues before they cause downtime. These protections give you peace of mind while maintaining peak productivity.

Final Thoughts: The Smart Choice for Your Nutrition Bar Business

Investing in our advanced Nutrition Bars Making Machine is more than just upgrading equipment – it's transforming your entire production approach. This complete nutrition bars production line represents the perfect marriage of speed, precision, and profitability that today's competitive market demands.

The benefits speak for themselves. You'll achieve consistent quality that builds brand loyalty while operating with efficiency that boosts your bottom line. The flexibility of our Nutrition Bars Process Line means you can adapt to changing consumer trends faster than competitors using outdated methods.

We understand this is a significant decision for your business. That's why we stand behind our technology with comprehensive support – from initial consultation to installation, training, and ongoing maintenance. Our team is committed to helping you maximize the potential of your new Nutrition Bars Making Machine.

The health snack industry continues growing at an impressive rate. With our nutrition bars production line, you'll be perfectly positioned to capitalize on this expansion. Whether expanding capacity, improving quality, or launching a new product line, this system gives you the tools to succeed.

Don't let production limitations hold your business back any longer. The right Nutrition Bars Process Line can be the difference between struggling to keep up and leading your market segment. The time to act is now – while demand for healthy, convenient nutrition bars has never been higher.

Take the next step today and discover how our Nutrition Bars Making Machine can revolutionize your operations. Contact our team for a personalized consultation and see firsthand what this technology can do for your specific needs and goals.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines