- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home>Products>Industrial Microwave Oven>Factory Use Microwave Insect silkworm chrysalis Tunnel Dehydrator Drying Machine Dryer

Factory Use Microwave Insect silkworm chrysalis Tunnel Dehydrator Drying Machine Dryer

Microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer drying by microwave drying process is an emerging drying technology equipment, which has the advantages of fast drying speed and good quality, and has become the insect drying equipment of choice for many insect farmers. All in all, only the perfect combination of formula-process-equipment can produce high-quality products.

- Insect silkworm chrysalis Tunnel Dehydrator Drying Machine

- Insect silkworm chrysalis Tunnel Dehydrator

- China

- CE,ISO9001,SGS ,BV

- 1Set of Insect silkworm chrysalis Tunnel Dehydrator Drying Machine

- Check with Insect silkworm chrysalis Tunnel Dehydrator Team

- 20days--35days

- L/C,T/T

- 20days/Insect silkworm chrysalis Drying Machine

Factory Use Microwave Insect silkworm chrysalis Tunnel Dehydrator Drying Machine Dryer Description

Microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer drying by microwave drying process is an emerging drying technology equipment, which has the advantages of fast drying speed and good quality, and has become the insect drying equipment of choice for many insect farmers. All in all, only the perfect combination of formula-process-equipment can produce high-quality products.

Sample Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine Dryer

Sample Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine Dryer

Introduction Of Microwave Insect Silkworm Chrysalis Tunnel Dehydrator Drying Machine Dryer

The insect dryer is a new type of environmental protection and energy-saving drying equipment developed and produced on the basis of microwave heating. The material is beautiful in color and can maintain the original appearance. After drying and drying, the water content is low, the puffing effect is obvious, it is easy to grind, and the active ingredients are well preserved.

Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine layout

Microwave Insect Silkworm Chrysalis Tunnel Dehydrator Drying Machine Dryer Parameters

|

Microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer technology |

|||||||||||

|

Model |

LY-12KWSP |

LY-20KWSP |

LY-30KWSP |

LY-40KWSP |

LY-50KWSP |

LY-60KWSP |

LY-70KWSP |

LY-80KWSP |

LY-100KWSP |

LY-150KWSP |

LY-200KWSP |

|

Power(KW) |

12 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

100 |

150 |

200 |

|

Dehydration capacity(Kg/h) |

12 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

100 |

150 |

200 |

|

Sterilization capacity(Kg/h) |

120-150 |

190-240 |

300-380 |

390-500 |

500-630 |

600-750 |

700-870 |

800-1000 |

1000-1250 |

1500-1850 |

2000-2500 |

Microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer performance

Microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer is used for drying insects such as locusts, locusts, earthworms, mealworms, black soldier fly larvae, centipedes, scorpions, etc. Greatly shortened, easy to control, straight worms, high degree of puffing, maintain color and freshness, less water and nutrient loss, low bacterial content, high processing efficiency, low cost, low energy consumption, small footprint, flexible operation, temperature uniform, good expansion, high degree of automation, programmable control, 24-hour continuous operation.

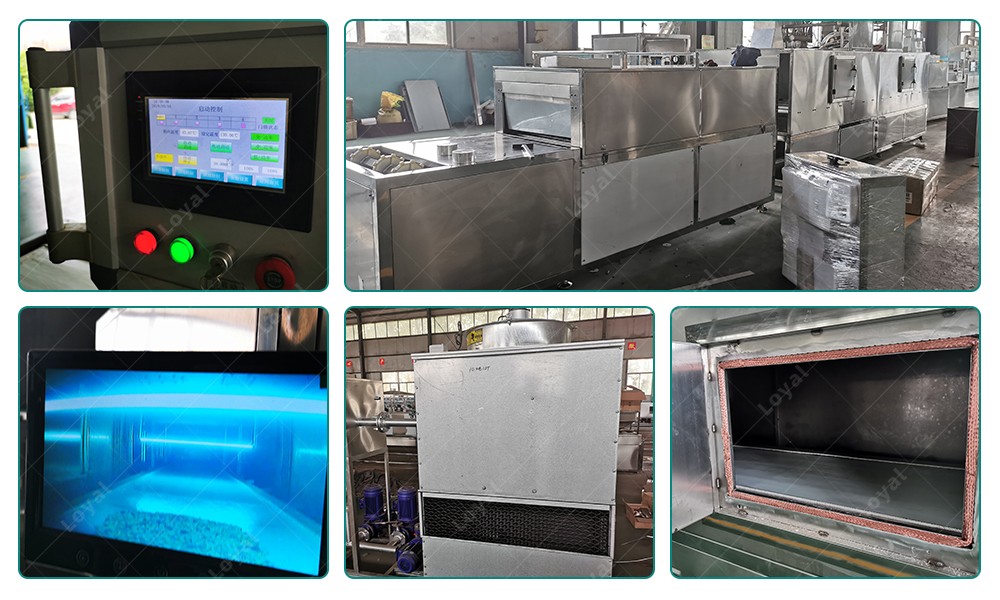

Detail of Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine

Microwave Insect Silkworm Chrysalis Tunnel Dehydrator Drying Machine Dryer Machine Advantages:

|

Technology of microwave insect silkworm chrysalis tunnel dehydrator drying machine dryer |

|

|

1. Dry |

The heating speed is fast, the heating time of the material is short, and it is not easy to cause some unnecessary chemical reactions of the material. |

|

2. Sterilization |

The microwave machine has the function of sterilization, which can kill fungi, molds, etc. |

|

3. Preservation |

Using a microwave is a great way to preserve the color, taste and nutrition of your food. |

|

4. Safety |

The machine is specially designed so that the microwave oven will not leak. And the machine does not generate additional pollution. |

|

5. Easy to operate |

Adopting plc makes the operation process simple, stable, safe and friendly. |

How Long Does It Take For Pinned Insects To Dry?

The microwave Tenebrio molitor drying machine developed and manufactured by Shandong Loyal can dry Tenebrio molitor 3-4 times faster than the traditional drying method, and it can be formed at one time, so as to meet the requirements of continuous production.

Test of Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine in factory

Test of Insect silkworm chrysalis of Microwave Tunnel Dehydrator Drying Machine in factory

How Do You Make Dry Insects?

The microwave heating principle of the insect dryer makes the polar molecules of the material rub back and forth with each other billions of times per second through high-frequency electromagnetic waves. The material itself generates a high temperature in a very short time, and the moisture contained in the material is composed of the inside migrates to the surface, and then evaporates into the atmosphere, and then the water vapor is discharged out of the equipment through the exhaust fan to achieve the purpose of drying, drying, puffing and sterilization.

|

The drying process of silkworm cocoon dryer is mainly divided into three stages: Preheating, constant speed drying and deceleration drying: |

|

|

The fresh cocoon is heated, and the heat energy penetrates into the cocoon cavity through the cocoon layer to kill the pupa, so that the water in the pupa enters the evaporation period. At this stage, the temperature should rise gradually and sharply. |

|

The period when the pupa has the most water evaporation and the fastest evaporation rate. During this period, the diffusion rate of water in the pupa is in a state of equilibrium with the evaporation rate on the surface of the cocoon layer. The temperature of the cocoon layer is lower than the air temperature in the drying room, and the temperature of the pupa body is lower than the temperature of the cocoon layer. Gradually lag behind the evaporation rate of the cocoon layer surface. |

|

The period in which the moisture in the segment cocoon gradually decreases and the evaporation rate correspondingly slows down. During this period, the temperature of the cocoon gradually increases to near the temperature of hot air. When the inside of the pupa begins to evaporate, the decelerated drying is transferred from the first stage to the second stage until the drying is over. |

How Can I Make My Insects Dry Faster?

Before baking silkworm cocoons with a heat pump cocoon dryer, it is necessary to find out the main process conditions of silkworm cocoon drying: Temperature, humidity, wind speed, cocoon laying volume and drying time. Cocoon quality has a greater impact. It must conform to the law of water evaporation in each stage of drying, such as the temperature should gradually decrease from high to low, the humidity should gradually increase from low to low, and the wind speed should gradually decrease from large to small.

Before baking silkworm cocoons with a heat pump cocoon dryer, it is necessary to find out the main process conditions of silkworm cocoon drying: Temperature, humidity, wind speed, cocoon laying volume and drying time. Cocoon quality has a greater impact. It must conform to the law of water evaporation in each stage of drying, such as the temperature should gradually decrease from high to low, the humidity should gradually increase from low to low, and the wind speed should gradually decrease from large to small.

The amount of cocoons in the cocoon dryer is calculated by the thickness of the cocoons, generally no more than 2 and a half cocoons lying horizontally.

Customer Purchase Case Of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

|

Customer cases for industrial sized microwave for factory in 2021 |

|

|

1 |

1t/h cost of microwave drying equipment sold in russia |

|

2 |

1t/h industrial microwave price for factory for sale in puerto rico |

|

3 |

1t/h industrial microwave price for sale in bolivia |

|

4 |

Senegal 1t/h industrial fully automatic industrial sized microwave |

|

5 |

1t/h industrial sized microwave for sale in côte d'ivoire |

|

6 |

China 300t/year industrial fully automatic industrial sized microwave |

|

Customer case of microwave drying equipment at 2021 |

|

|

1 |

1t/h microwave drying equipment for factory in uzbekistan |

|

2 |

1000kg/h industrial microwave drying equipment for sale in senegal |

|

3 |

Mozambique 1t/h fully automatic microwave drying equipment |

|

4 |

Bangladesh 2t/h fully automatic microwave drying equipment |

|

Dealed customer have technology of microwave drying equipment at 2021 |

|

|

1 |

1t/h thai microwave drying equipment for factory |

|

2 |

Uzbekistan 1t/h fully automatic industrial microwave price |

|

3 |

Usa 1t/h microwave drying equipment |

|

4 |

800kg/h industrial microwave drying equipment for sale in nigeria |

Related Videos

| Industrial Dryer for Yellow Mealworm Drying |

| The drying of yellow mealworm |

Related News

| 800 Kg/H Industrial Microwave Locust Grasshopper Drying Baking Oven Machine For Sale In Russia |

| Microwave Conveyor Belt With 500KG/H Grasshopper Larvae Drying Machine Oven Will Be Shipped To Indonesia |

| Pet Feed Microwave Sterilization Equipment - Shanghai Mr. Xu visit |

Product Categories

- Macaroni Production Machine

- Instant Noodle Machine

- Biscuit Making Machine

- Nutrition Bar Manufacturing Equipment

- Bread Crumb Machine

- Food Extruder Machine

- Corn Flakes Production Line

- Corn Puff Snacks Production Line

- Nutritional Baby Rice Powder Food Machine

- Dog Food Manufacturing Equipment

- Feed Production Line

- Cold Pressed Pet Food Machine

- Soya Nuggets Extruder

- Artificial Rice Production Line

- Doritos chips making machine

- Pellet Snack Making Machine

- Modified Starch Machine

- Kurkure Manufacturing Machine

- Industrial Microwave Oven

- Fried Dough Extruder Machine

- Industrial Deep Fat Fryer

- Wafer Line

- Automatic Packaging Machine

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -The Qihe Yellow River Material Warehouse, No. 689, Meili North Road, Jinan City, Shandong Prov

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine

150Kw Fully Automatic Industrial Continuous Microwave Shrimp Drying Machine Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment

Continuous Tunnel Honeysuckle Flower Drying Dehydrator Machine Tunnel Microwave Baking And Sterilizing Equipment Automatic Microwave Frozen Meat Beef Thawing Machine

Automatic Microwave Frozen Meat Beef Thawing Machine Hot Sale Industrial Stainless Steel Gelatin Microwave Dryer

Hot Sale Industrial Stainless Steel Gelatin Microwave Dryer