- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Company News> The Ultimate Industrial Microwave Machinery Guide to 2024

The Ultimate Industrial Microwave Machinery Guide to 2024

2024-04-28 17:30:11Introduction to Industrial Microwave Machinery

Industrial microwave machinery revolutionizes food processing by utilizing microwave energy for drying, heating, and sterilization. Unlike conventional methods, which rely on convection or conduction, industrial microwave machines generate heat within the product itself, resulting in faster processing times and superior quality. These machines consist of specialized chambers equipped with microwave generators and control systems to ensure precise and efficient operation. Let's delve deeper into the workings of industrial microwave machinery and its significance in the food industry.

Advantages of Industrial Microwave Technology

Industrial microwave technology offers numerous advantages over traditional drying methods. Firstly, it significantly reduces processing time, enabling faster production cycles and increased throughput. Unlike conventional drying, which can take hours or even days, industrial microwave machinery can achieve the same results in a fraction of the time, thereby improving overall efficiency and productivity.

Secondly, industrial microwave drying preserves the quality and nutritional value of food products better than conventional methods. By heating the product evenly and gently from the inside out, microwave technology minimizes heat exposure, reducing the risk of overcooking, nutrient degradation, and flavor loss. This results in products that retain their natural color, texture, and taste, appealing to consumers who prioritize quality and health benefits.

Furthermore, industrial microwave machinery offers versatility in processing a wide range of food products, including fruits, vegetables, meats, grains, and snacks. From drying and pasteurization to thawing and tempering, microwave technology can accommodate various processing needs, making it a versatile solution for food manufacturers.

Lastly, industrial microwave technology is energy-efficient and environmentally friendly. Unlike traditional methods that rely on fossil fuels or electric resistance heating, microwave energy heats the product directly, minimizing energy waste and reducing carbon emissions. This not only lowers operational costs but also aligns with sustainable practices, making industrial microwave machinery an attractive choice for environmentally conscious companies.

Applications of Industrial Microwave Machinery

Industrial microwave machinery finds diverse applications across the food processing industry, owing to its efficiency and versatility. Let's explore some of the key applications where industrial microwave machinery excels:

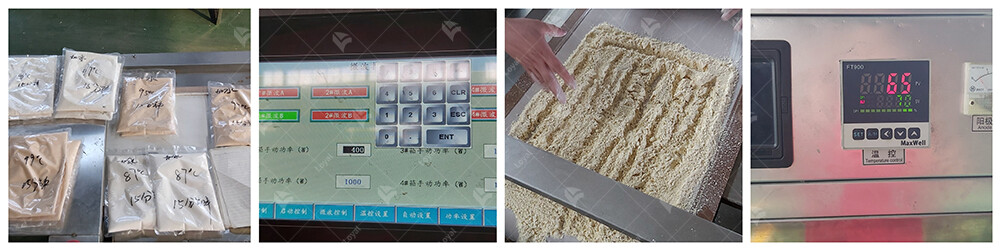

1. Food Drying: Industrial microwave machinery is extensively used for drying various food products such as fruits, vegetables, herbs, and grains. The microwave energy penetrates the food material, heating it evenly and quickly, resulting in reduced drying times compared to conventional methods. This application is particularly beneficial for preserving the nutritional quality and flavor of the food products.

2. Sterilization and Pasteurization: Industrial microwave machinery is employed for sterilizing and pasteurizing food products to ensure their safety and extend shelf life. Microwave energy effectively destroys pathogens, bacteria, and other harmful microorganisms present in the food, making it suitable for consumption without the need for excessive heat or chemical additives. This application is crucial for maintaining food safety standards and reducing the risk of foodborne illnesses.

3. Thawing and Defrosting: Industrial microwave machinery is used for rapid thawing and defrosting of frozen food products, such as meat, poultry, seafood, and ready-to-eat meals. Microwave energy penetrates the frozen material, quickly and evenly heating it from the inside out, eliminating the need for prolonged thawing periods. This application enables food processors to efficiently manage inventory and meet consumer demand for conveniently thawed products.

4. Cooking and Baking: Industrial microwave machinery is employed for cooking and baking a wide range of food products, including snacks, baked goods, convenience meals, and pre-cooked ingredients. Microwave cooking offers advantages such as faster cooking times, uniform heating, and energy efficiency. Additionally, it allows for precise control over cooking parameters, resulting in consistent quality and taste across batches. This application caters to the growing demand for convenient, ready-to-eat food options in the market.

Key Components of Industrial Microwave Equipment

Industrial microwave equipment comprises several essential components that work together to generate and control microwave energy for food processing applications. Here are the key components of industrial microwave equipment:

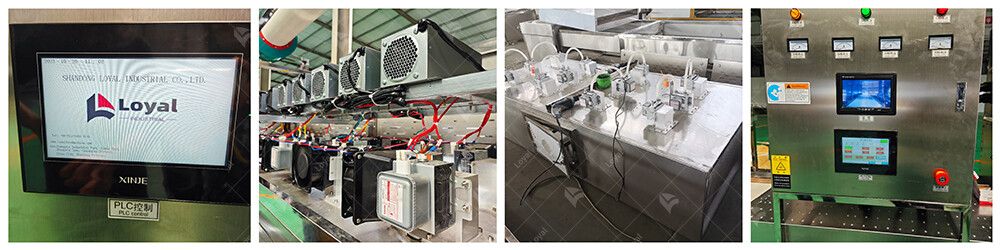

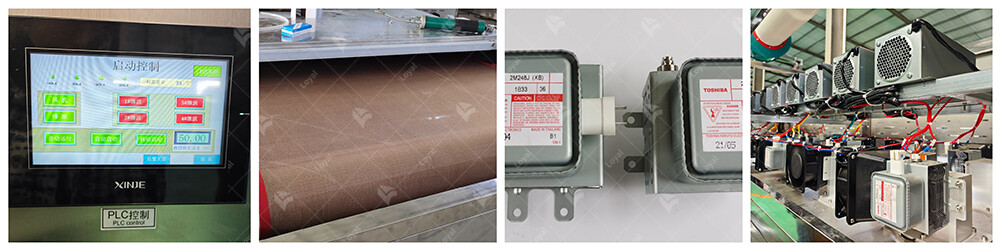

1. Magnetron: The magnetron is the heart of the industrial microwave system, responsible for generating microwave energy. It converts electrical energy into electromagnetic waves at the desired frequency, typically 2450 MHz for food processing applications.

2. Waveguide: The waveguide is a metal tube that guides the microwave energy from the magnetron to the processing chamber. It ensures efficient transmission of microwave energy while minimizing energy loss.

3. Processing Chamber: The processing chamber is the enclosure where the food products are placed for microwave processing. It is designed to contain and direct the microwave energy onto the food material uniformly. The chamber may feature rotating trays or conveyor belts for even exposure to microwave energy.

4. Control System: The control system consists of electronic controls and sensors that regulate various parameters such as microwave power, time, and temperature during the processing cycle. It ensures precise control over the processing conditions to achieve desired results consistently.

Operating Principles of Industrial Microwave Machinery

Industrial microwave machinery operates on the principle of electromagnetic radiation to generate heat within the material being processed. These machines utilize microwaves, which are a form of electromagnetic energy, to rapidly and uniformly heat the material. The microwaves are produced by a magnetron, a specialized vacuum tube that converts electrical energy into microwave radiation.

The material to be dried or processed is placed inside the industrial microwave machinery, typically on a conveyor belt or tray. When the machine is activated, the magnetron emits microwaves at a specific frequency, typically around 2450 MHz. These microwaves penetrate the material and interact with its molecules, causing them to oscillate rapidly. This molecular friction generates heat, leading to the rapid and efficient drying or processing of the material.

As the material heats up, moisture within it evaporates, resulting in drying. The precise control of microwave power and frequency allows for uniform heating throughout the material, reducing processing times and preserving product quality. Industrial microwave machinery can be programmed with specific parameters such as temperature, power level, and processing time to achieve optimal results for different types of materials.

Safety Measures for Industrial Microwave Processing

Safety is paramount when operating industrial microwave machinery to ensure the well-being of operators and the integrity of the product. One essential safety measure is to implement proper shielding to contain the microwave radiation within the processing chamber. This prevents exposure to harmful radiation and minimizes the risk of leakage, which could pose health hazards to personnel.

Furthermore, it is crucial to follow strict operating procedures and guidelines provided by the manufacturer to prevent accidents and ensure the safe operation of the equipment. This includes proper maintenance of the machinery, regular inspection of components, and adherence to recommended operating parameters.

Operators should also be trained in microwave safety protocols, including the use of personal protective equipment such as gloves and safety glasses. They should be aware of potential hazards associated with microwave processing, such as thermal burns from hot surfaces and materials, and take appropriate precautions to mitigate risks.

Industrial microwave machinery should be equipped with safety features such as emergency stop buttons and interlock systems to shut down the equipment in case of malfunction or operator error. Regular safety audits and risk assessments should be conducted to identify and address any potential hazards in the workplace. By implementing these safety measures, industrial microwave processing can be conducted efficiently and securely, ensuring the quality and safety of the final product.

Maintenance Tips for Industrial Microwave Equipment

Maintaining industrial microwave equipment is essential for ensuring optimal performance and longevity. Here are some expert tips to keep your industrial microwave machinery in top condition:

1. Regular Cleaning: Regular cleaning of industrial microwave equipment is crucial to prevent the buildup of food residues and contaminants. Use mild detergents and non-abrasive cleaning materials to avoid damaging sensitive components. Pay special attention to the microwave cavity, waveguide, and ventilation system to ensure efficient operation.

2. Inspect and Replace Components: Conduct routine inspections of industrial microwave machinery to identify any signs of wear or damage. Inspect components such as the magnetron, waveguide, power supply, and control panel for signs of corrosion, loose connections, or overheating. Replace worn-out or damaged parts promptly to prevent equipment failure and ensure safety.

3. Calibration and Alignment: Periodically calibrate and align the components of industrial microwave equipment to maintain optimal performance. Proper alignment of the magnetron, waveguide, and reflectors ensures uniform heating and energy efficiency. Use specialized tools and follow manufacturer guidelines to perform calibration procedures accurately.

4. Ventilation Maintenance: Proper ventilation is essential for dissipating heat generated during microwave processing and preventing overheating of equipment components. Ensure that ventilation systems, including fans and filters, are clean and free from obstructions. Regularly inspect and clean ventilation ducts to maintain airflow and prevent the accumulation of dust and debris.

Energy Efficiency in Industrial Microwave Processing

Achieving energy efficiency in industrial microwave processing is vital for reducing operational costs and minimizing environmental impact. Here are some strategies to improve energy efficiency in industrial microwave processing:

1. Optimized Process Parameters: Adjusting process parameters such as power level, time, and temperature according to product requirements can significantly improve energy efficiency. Opt for lower power levels and shorter processing times whenever possible to minimize energy consumption while maintaining product quality.

2. Load Optimization: Proper load distribution and arrangement within the microwave cavity can enhance energy efficiency by maximizing the utilization of microwave energy. Avoid overloading or underloading the microwave chamber, as this can lead to uneven heating and energy wastage. Arrange products evenly and maintain sufficient spacing between them to ensure uniform heating.

3. Insulation and Seal Maintenance: Insulating the microwave chamber and maintaining tight seals help minimize heat loss and improve energy efficiency. Check for any gaps or leaks in the insulation and seals regularly and repair or replace them as needed. Proper insulation ensures that microwave energy is efficiently utilized for heating the product rather than escaping into the surrounding environment.

4. Advanced Control Systems: Upgrading to advanced control systems with features such as automatic power adjustment, temperature monitoring, and energy-saving modes can optimize energy usage during microwave processing. These systems allow for precise control of process parameters and energy consumption, leading to significant energy savings over time.

Implementing these maintenance tips and energy efficiency strategies can help maximize the performance and sustainability of industrial microwave equipment, ultimately contributing to cost savings and environmental stewardship.

Emerging Trends in Industrial Microwave Technology

One notable trend is the integration of smart technology into industrial microwave machinery. Manufacturers are incorporating IoT (Internet of Things) sensors and connectivity features into equipment, allowing for remote monitoring and control of drying processes. This advancement enhances operational efficiency, reduces downtime, and enables predictive maintenance, ultimately optimizing overall production outcomes.

Another trend is the development of hybrid drying systems combining microwave technology with other drying methods such as convection or infrared heating. These hybrid systems capitalize on the strengths of each drying technique, resulting in faster processing times, improved energy efficiency, and enhanced product quality. By leveraging synergies between different drying methods, manufacturers can meet diverse processing requirements while minimizing drawbacks associated with individual techniques.

There is a growing emphasis on sustainability in industrial microwave technology. Manufacturers are exploring eco-friendly materials for equipment construction and implementing energy-saving features to minimize environmental impact. Additionally, research efforts are directed towards maximizing the utilization of renewable energy sources to power microwave machinery, further reducing carbon footprint and operating costs.

Future Prospects of Industrial Microwave Machinery

One significant prospect is the continued refinement of microwave drying processes to enhance efficiency and product quality. Research efforts are focused on optimizing drying parameters, exploring novel microwave frequencies and power levels, and developing advanced control algorithms to achieve precise moisture removal while preserving the nutritional integrity and sensory attributes of food products. These advancements will enable manufacturers to meet stringent quality standards and consumer preferences, fostering growth and competitiveness in the food processing industry.

Another prospect is the expansion of applications for industrial microwave machinery beyond traditional food processing. Industries such as pharmaceuticals, chemicals, textiles, and ceramics are increasingly adopting microwave technology for various drying, curing, and sterilization applications. As awareness of the benefits of microwave processing continues to grow, the demand for specialized microwave equipment tailored to the specific requirements of these industries is expected to rise, opening up new opportunities for innovation and market expansion.

Moreover, advancements in materials science and engineering will lead to the development of more durable, cost-effective, and sustainable microwave components and systems. Innovations such as advanced ceramics, high-temperature superconductors, and eco-friendly insulation materials will improve the performance, reliability, and environmental footprint of industrial microwave machinery, making it more accessible and attractive to a broader range of industries and applications.

In conclusion, the future prospects of industrial microwave machinery are characterized by continued innovation, diversification of applications, and integration of advanced technologies. As research and development efforts progress and market demands evolve, industrial microwave equipment will play an increasingly pivotal role in driving efficiency, sustainability, and competitiveness across various industries, shaping the future of manufacturing and processing operations.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines