- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> Unlock The Secrets Of Efficient Cereal bar production line Manufacturing

Unlock The Secrets Of Efficient Cereal bar production line Manufacturing

2025-05-30 16:44:25If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/foodmachineloyal

Cereal Bar Production Line Detail Introduction

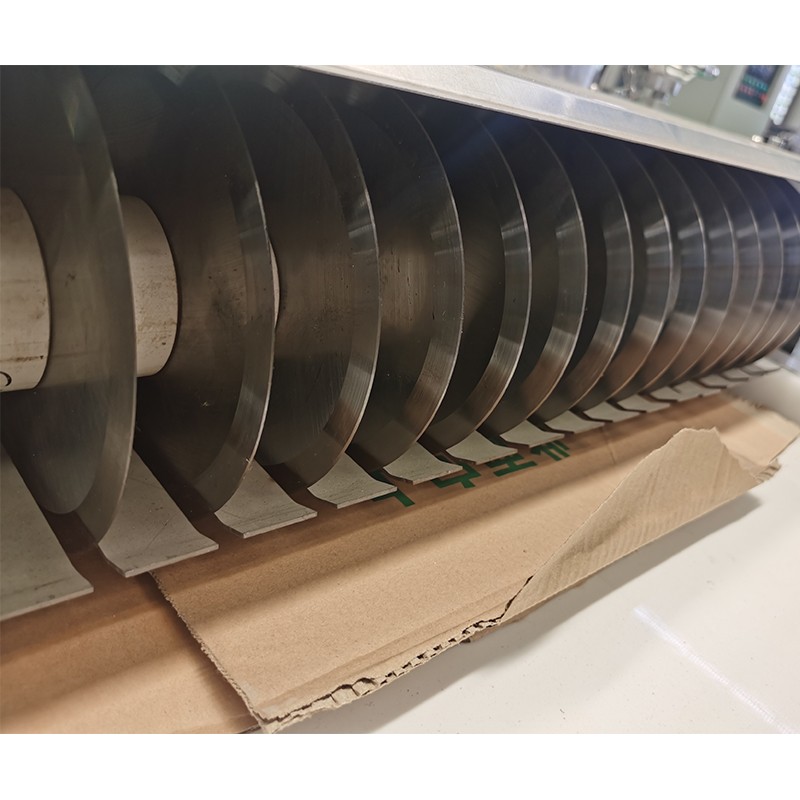

A cereal bar machine is a type of food processing equipment that combines various ingredients like grains, nuts, fruits, and sweeteners to produce cereal bars in diverse shapes and sizes. This machine typically encompasses several components, including a mixing unit, a pressing roller, a cooling conveyor, and a cutting system. The integration of these components allows for a seamless production line, from mixing ingredients to packaging finished cereal bars.

The versatility of the machine also stands out, as it can handle a wide range of ingredients and incorporate various additives, such as vitamins and minerals, to enhance the nutritional value of the bars. Furthermore, modern cereal bar machines are designed with flexibility in mind, allowing manufacturers to easily switch between recipes and bar shapes to meet changing consumer demands.

As a leading cereal bar production line manufacturer in the industry, we are fully aware of the significant responsibilities energy bar production line’ve been carrying in cereal bar manufacturing process.

To promote the development of the protein cereal bar industry and become a role modle for the majority of cereal bar line manufacturers, we have always been energy bar manufacturing equipment concentraring on innovation over the years that is innovation is the driving force of cereal bar proccess technological progress.

The automatic energy bar manufacturing equipment is mainly used for the food processing and molding produced in medium and large scale food industry, such as satsuma, rice bar, sesame snack candy bar, peanut candy bar, sunflower seeds candy bar, cereal bar, and other molding and cutting.

Cereal Bar Mixer — screw conveyer— Twin-screw extruder —Sifter—Air conveyer —Flaking machine —Air conveyer — Multi-layer oven — Hoister — High Temperature Roaster Oven —Melting sugar machine —Sprayer sugar—Hoister —Roller — Air compressor— Hoister — Multi-layer oven— Cooling machine

|

List Complete Of Energy Nutrition Bar Production Line |

|

|

Energy Bar Machine Name |

Capacity |

|

1.Sugar Melting Pot |

100L |

|

200L |

|

|

2.Mixer |

3-8kg/Time |

|

12-20kg/Time |

|

|

3.Cereal Molding Machine |

150-200kg/H |

|

4.Cereal Bar Cutter |

50-100kg/H |

Parts of cereal bar production line

The cereal bar production line is made up of a variety of equipment. Manufacturers can match according to their needs, thus making it the most suitable production line. The basic equipment of the production line is as follows.

1. Cereal bar boiling sugar pot: boiling sugar syrup, the most basic equipment, the basis of producing cereal bars.

2. Cereal bar forming machine: It can press the mixed raw materials. The quality of pressing is crucial. The hard and crispy state is the highest quality standard.

3. Cereal bar drying machine: It can dry the produced cereal bar quickly. The dried cereal bar has a richer taste, more prominent flavor and longer shelf life.

4. Coating line: The cereal bar can be further seasoned.

5. Cooling conveyor: It is suitable for transporting the products processed from the dryer, which can cool down the cereal bars quickly.

How to troubleshoot cereal bar production line?

During a long period of use, the complete cereal bar process line will experience certain wear and tear and a variety of faults will occur. The following are a few common troubleshooting methods for cereal bar making machines.

1. Check all the power, gas and hydraulic sources for protein bar plant. Problems with these parts will lead to failures, such as failure of the workshop power supply, low power supply, burnt insurance, poor contact with the power plug, etc.

2. Check whether the protein bar extruder machine sensor position is offset. You need to check this part when you meet sensor failure, sensitivity failure, etc.

3. Check the relays, flow control valves for whole cereal bar plant , pressure control valves. Like magnetic induction sensors, relays will also have overlap sticking in long-term use, thus failing to ensure the normal electrical circuit and needing replacement. These devices, like sensors, are components that require routine maintenance.

4. Check electrical, pneumatic and hydraulic circuit connections. If none of the above three steps reveal any problems, then check all circuits. Look for broken wires in the circuits, check for damaging creases in the pneumatic tubing, and check for blockages in the hydraulic oil lines.

5. Check the cereal bar line controller. If none of the above parts show any problem, then the fault may appear in the controller.

What is Cereal Bar Process Line?

Cereals bar production is a fully automatic multifunctional cereal bar process line. At the same time, the manufacturer based on years of experience and advanced technology to develop it. What’s more, it can produce fruit bars, cereal bars, nutrition bars and nougat.

Cereals bar production is a fully automatic multifunctional cereal bar making machine. At the same time, the manufacturer based on years of experience and advanced technology to develop it. What’s more, it can produce fruit bars, cereal bars, nutrition bars and nougat. It it also fit for many types of snack foods on the market. And also its material is the kind of food-grade stainless steel. So it can ensure the safety and sanitation of food and make consumers more at ease. For manufacturers, this machine has a very high production efficiency.

Then it can realize the high productivity. And also they can get the higher economic benefits. At the same time, it is a rare high-quality equipment on the market today. Cereals bar production mainly uses chocolate, rice, oats, etc. as the main raw materials. After mixing, cutting, cooking and packaging, it can make the final production. Such as cereal bars, peanut bars, candy bars and other snack foods. What’s more, cereals bar production uses the frequency converter to control the speed. And then in order to get mass production. At the same time, manufacturers can provide free installation and training services.

And then it can truly solve all worries for buyers. What’s more, it is one of the most representative equipment in the food industry. Cereals bar production is one of the best-selling production lines in modern industry. Also using it can produce the high-quality foods. Such as corn bars, cereal bars and other snack foods. At the same time, the final foods is very popular among buyers. And both taste and look of food can get to the top level. What’s more, it is also very convenient to use. Then whether installation and maintenance or manual operation, it is very simple. So it can reduce the difficulty of use. At the same time, it allows more manufacturers to get the benefit.

The automatic nutrition cereal bar production line is an automatic production line composed of nutritional bar equipment such as heat preservation mixer, flattening machine, cross cutting machine, vertical cutting machine and so on.

The nutrition Cereal Bar Production Line realizes automatic and intelligent operation and continuous feeding, and consists of automatic flattening, automatic cross-cutting and automatic vertical cutting; seven automatic leveling, the leveling density is moderate, the thickness is uniform; frequency conversion adjustment, accurate cutting size, forming The squareness is good; the whole cereal bar making machine is produced continuously, and no manual connection is required in the middle.

The surface of each nutrition cereal bar machine is made of 304 stainless steel material, which is suitable for automatic molding of series of coarse grains such as popcorn candy, reeses puffs, energy bar, peanut butter cheerio bars, nut cake, egg tallow cake, corn cake and so on.

What are the materials used to make the cereal bars?

Energy bars, as the name suggests, are bar foods that supplement energy. It is the wife of a marathon runner - a sports nutrition food specially developed by a nutritionist.

Energy bars are mainly composed of carbohydrates and proteins. Suitable for adults. It originated in 1985 and has only a short history of over 30 years. Although the energy bar started late, it has developed rapidly, both in terms of technology content and sales volume. In the United States alone, 700 million energy bars were sold in 2002.

The recipe of cereal bar usually consists of cereals, nuts, fats and binders. Cereals usually account for 10% to 40%, mainly oats, puffed rice, but also for instance, wheat, barley, corn, buckwheat, barley and other grains are added. Nuts are mainly walnuts, peanuts, bataan wood, cashews, hazelnuts, etc.. The amount added generally accounts for 10% to 30% of the total. Fats and oils are mainly creams, margarine and so on. The amount added is generally 10% to 15%. The main components of the binder are syrup, maltodextrin, starch paste, edible gum, condensed milk, etc. The amount added is about 30% to 40%.

High speed automatic chocolate coated fruit bar making machine is mainly developed for making protein bar, date bar and fruit bar. We would be delighted to explore production details of the next great food bar Production Line.

Are the cereal bars healthy?

Food-grade stainless steel refers to the part of the cereal bar line equipment that comes into contact with food, and must comply with the corresponding food safety regulations.

The energy bar manufacturing equipment is healthy and safe, using food grade 304 stainless steel.

The 304 stainless steel material has been tested and found that it is lower than the standard value stipulated by the European drinking water law, and it can reduce the pipeline pressure, thereby reducing the transportation cost. Whether it is used for hot water or cold water, it can be recycled.

Although the slogan of many cereal bars on the market today is "healthy and low-fat," but the fact does not seem to be the case. A lot of sugar will be added in the production process, making the sugar content seriously excessive. It brings a very big health risk to consumers. Long-term consumption of large amounts will potentially result in obesity, thereby, increasing the risk of hypertension, hyperlipidemia and cardiovascular and cerebrovascular diseases.

For people who want to use cereal bars as a meal replacement, it is recommended to buy cereal bars with lower sugar content so as not to cause any health hazards and to obtain a healthier lifestyle.

What is the future of cereal bar production line?

Cereal bar energy bar protein bar is currently very popular casual food and breakfast cereal bar, there is a large consumer market. Research shows that taste is the leading factor for consumers to purchase cereal bars, followed by crunchiness and chewiness, and that products that are easy to carry and consume can also cause consumers to be willing to buy.

Therefore, at present, low-fat, low-sugar, low-calorie energy protein cereal bar products meet the market demand.

More and more businesses will add antioxidant ingredients to their products, such as Knorr's adding a variety of fruits to their breakfast cereals. Antioxidants can be provided by antioxidants or fruits.

Super Fruit Fusion Cereal Bar, which has added strawberries, blueberries and other fruits. The product is certified by kosher to be rich in vitamin C and vitamin E.

With changing consumer attitudes, more and more consumers are not only concerned about the taste and convenience of the cereal bar, but whether it is healthy is also one of the important indicators for today's consumers to buy.

Benefits of cereal bar process line

cereal bar making machine greatly improves labor productivity. That is, more products can be manufactured per unit of time, and each labor input can create higher output value, and workers can be freed from regular manual labor to engage in more creative work.

Second, product quality has a high degree of repeatability and consistency, and the cereal bar manufacturing process can significantly reduce the failure rate.

Third, protein bar extruder machine significantly reduce manufacturing costs. Machine automation assembly production is very short beat, can achieve high productivity, while Protein Bar Production Line can run continuously, so in the conditions of mass production can significantly reduce manufacturing costs.

Nutrition bar making machine adopts various high-precision guiding, positioning, feeding, adjusting, detecting and vision systems or components to ensure high precision of product assembly and production.

Automatic protein bar extruder shortens the manufacturing cycle and reduces the quantity of products. cereal bar forming machine automation shortens the manufacturing cycle of products, which can enable enterprises to achieve rapid delivery and improve their competitiveness in the market, while cereal bar cutting machine can also reduce the number of raw materials and products, reduce the cost of working capital.

Sixth, in automatic energy bar production line harmless to human body environment to replace manual operation.

Seven, automatic protein bar extruder relies on machine automation production. At present, the energy bar production line on the market is increasingly miniaturized and miniaturized, the size of the parts is significantly reduced, and various microelectromechanical systems are rapidly developing.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com

Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines