- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home> Processing> What Are The Advantages Of Biodegradable Drinking Straws Extruder Equipment

What Are The Advantages Of Biodegradable Drinking Straws Extruder Equipment

2020-09-12 11:45:471. Description Of Edible Rice Flour Drinking Straw Making Machine

With the severe global warming and the increasing awareness of environmental protection, the green and environmentally friendly rice edible straws have attracted everyone's attention.

Small environmentally rice straw equipment uses rice flour, corn flour, and cassava flour as the main raw materials. After extensive verification, it does not affect the absorption of fluid dairy products, that is, it will not melt, and can be eaten, without pollution, and can be environmentally friendly. the goal of. The raw materials of pasta drinking straws making machine are made into blanks of various sizes by a single screw extruder, and then dried to form a straw with a smooth surface and a realistic shape; our unit screw combination technology and precise control of the production process can make your raw materials more choices, higher product quality, and more variety.

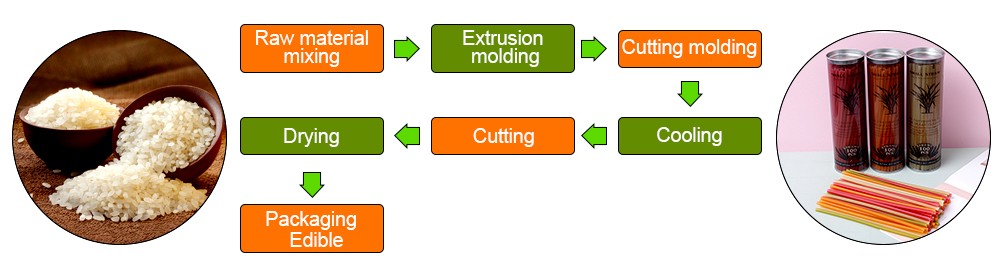

2. Production Process Of Drinking Rice Straw Making Machine

Mixing-Puffing-Cutting-Cooling-Drying-Cooling-Packaging

3. Advantages Of Biodegradable Drinking Straws Making Machine

Single-screw extruder series consists of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system, mainly used for processing rice straws.

|

1 |

The extruder feeding system, drive system and rotary cutting system all adopt frequency conversion speed regulation, with strong power and balanced operation. |

|

2 |

The extruder screw, barrel and die are all designed with a circulating cooling system to ensure the temperature balance of the raw materials during extrusion. |

|

3 |

For different raw materials, single-screw and twin-screw feeding systems are selected to ensure uniform, stable and reliable feeding. |

|

4 |

The screw is processed by a special process, wear-resistant, anti-fatigue, and has a long service life. |

|

5 |

Different screw length-to-diameter ratio structures meet different process requirements |

Biodegradable Rice Drinking Straw Processing Line

Biodegradable Rice Drinking Straw Processing Line Drinking Rice Straw Making Machine

Drinking Rice Straw Making Machine Edible Rice Flour Drinking Straw Making Machine

Edible Rice Flour Drinking Straw Making Machine Corn Starch Straw Making Machine

Corn Starch Straw Making Machine Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Automatic Cookies Making Machines

Automatic Cookies Making Machines Fully Automatic Biscuit Making Machines

Fully Automatic Biscuit Making Machines