- Shandong Loyal Industrial Co.,Ltd.

- Macaroni Production Machine Instant Noodle Machine Biscuit Making Machine

Home>Products>Macaroni Production Machine>Instant Pasta Production Line

Instant Pasta Production Line

- Loyal

- China

- CE,ISO9001,SGS ,BV

- 1Set

- Contact Us

- Wooden case or wooden pellets depended on clients' require

- 20days /industrial noodle making machine

Instant Pasta Production Line Description

Overview of Instant Pasta Production Line

In today's fast-paced world, convenience is paramount, especially in the realm of food consumption. One of the most convenient options gaining popularity is instant pasta. With the rise in demand for quick and easy meal solutions, precooked pasta production lines have become essential in meeting consumer needs. These production lines streamline the process of creating precooked pasta, ensuring efficiency and consistency in the final product.

Instant Pasta Cup production lines have revolutionized the way pasta is consumed on-the-go. These lines are equipped to produce individual servings of precooked pasta, conveniently packaged in portable cups. Whether it's a quick lunch at the office or a snack on a road trip, instant pasta cups offer a delicious and hassle-free solution for busy individuals.

The heart of any instant pasta production line lies in its ability to cook and package pasta quickly without compromising quality. Advanced technology and automated systems ensure that each batch of pasta is cooked to perfection, with the right texture and flavor. From mixing and kneading the dough to shaping and cooking the pasta, every step is meticulously controlled to produce consistent results.

There's no denying that pasta is a healthy choice. Its consumption is steadily increasing worldwide, appealing to vegans, vegetarians, health enthusiasts, and everyone in between. It's a product that satisfies the demands and preferences of various segments of the food market.

The only challenge lies in the cooking time required for both the pasta itself and its accompanying sauces.

Loyalty Tech revolutionizes pasta-making by melding tradition with a novel, natural, and wholesome approach. Through gentle extrusion, meticulous steam pressure control during cooking, and uniform drying, we craft a product that requires no cooking, merely a swift 2-3 minute rehydration. Our instant pasta pairs seamlessly with an array of sauces and toppings, offering a delicious and nutritious substitute for fat-laden, sodium-rich.

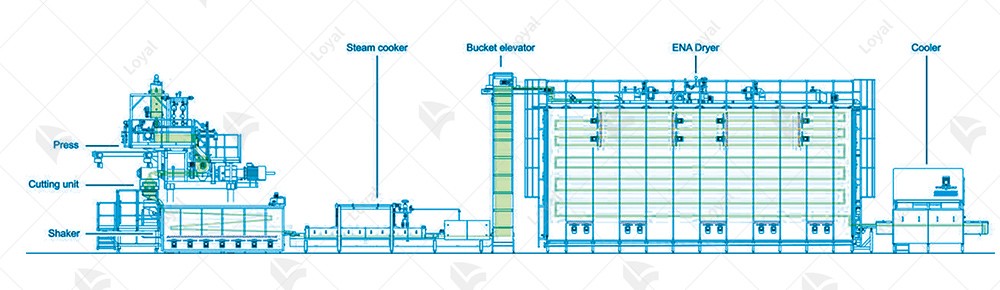

Instant pasta production line production process

RAW MATERIAL HANDLING --VACUUM EXTRUDER SHAPING --PRE-RIPENING --PRE-DRYING --DRYING --COOLING --PACKING

Work flow description of instant pasta production line

Vacuum Mixing&Shaping

The pasta production process begins in the vacuum mixing tank, where raw materials and water are precisely measured to create the dough. With the help of high-efficiency compression screws, the dough achieves the perfect density required for maintaining its shape as it exits the die head. The press is equipped with Total Vacuum System Technology to ensure optimal results.

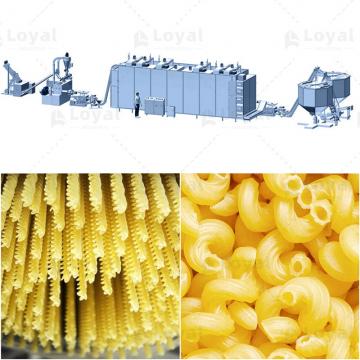

The cutting system for macaroni is an independent unit, capable of producing various shapes of short-cut elbow macaroni by simply changing the molds, such as spirals, bends, large bends, small bends, stars, small flowers, etc.

Vibrating pre-drying and Bucket Elevator

The pasta drying process commences at this stage. Equipped with a novel motion mechanism (patented), the shaker enables considerable energy conservation. Within the shaker, the pasta surface undergoes rapid drying via hot air, preventing sticking in subsequent stages of pasta production.

Instant Pasta Steam Pre-Cooking

Our gelatinization system guarantees a consistently uniform final product, enhancing quality upon moisture restoration.

To achieve uniform and thorough cooking of instant pasta, this equipment features an innovative low-pressure steam diffusion system. The steam cooker's conveyor belt is crafted from self-cleaning PIK material, ideal for high temperatures.

Dryer

The pasta drying process occurs in two distinct zones within the dryer: the pre-dryer and the main dryer. Each zone is equipped with separate thermohygroregulation control units. Following a pre-drying stage lasting approximately 40 minutes, there's a drying phase of about 2 hours, followed by a stabilization phase of roughly 30 minutes. This ensures high-quality production with a variety of raw materials. The dryer features high-density fiberglass panels, internally lined with stainless steel sheets and silicone rubber gaskets for durability and efficiency.

Cooler

The air/water cooler features an external cooling unit designed to reduce the pasta temperature, making it suitable for storage or packaging purposes.

Application of instant pasta production line

|

Barilla Ready Pasta

|

|

Knorr Instant Cup

|

|

Instant Pasta Cup - Basilio

|

|

Halal Instant Cup Baked Pasta Noodle

|

|

Instant Cup Pasta

|

|

Huel Instant Meal Cups

|

|

Tutto Bene Cups

|

|

Instant Microwave Pasta

|

Instant pasta production line machine features & advantages

|

Enhanced Efficiency |

Instant elbow macaroni machines operate under vacuum conditions, ensuring optimal efficiency throughout the production process.

|

|

Superior Drying Performance |

These machines boast exceptional drying capabilities, resulting in quick and thorough drying of the pasta, maintaining its quality and texture.

|

|

Consistent Quality |

The vacuum and drying features of these machines contribute to the consistent quality of the final product, meeting the highest standards of excellence.

|

|

Versatility |

Instant elbow macaroni machines offer versatility, accommodating various pasta shapes and sizes, catering to diverse consumer preferences.

|

|

Increased Shelf Life |

By effectively reducing moisture content through vacuum and drying processes, these machines help extend the shelf life of the instant elbow macaroni, ensuring freshness and quality over time.

|

Regarding the instant pasta production line, the services we provide

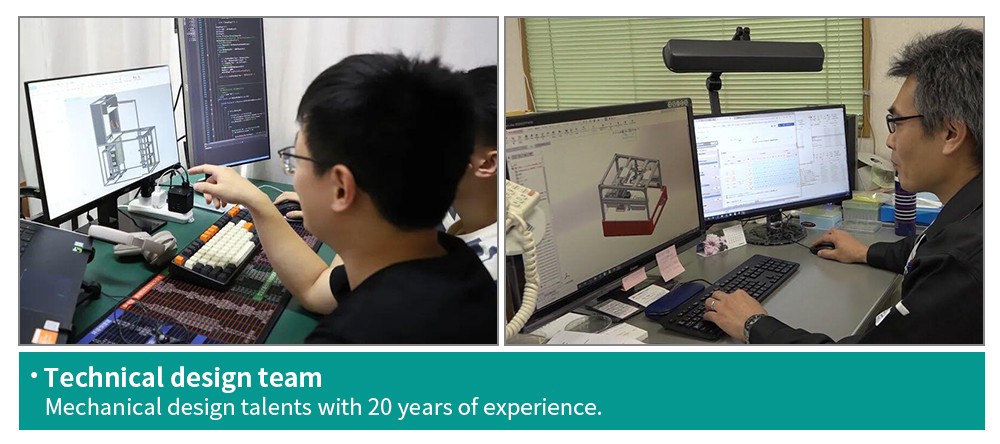

”SINCERITY IS THE SOUL OF LOYAL ” Loyal’s vision is to create value for every customer, which inspires us-inspires us-to do what we do. With 20 years experience at the food machine field, We provide feasible solutions for every customer, from A to Z, from raw material processing to finished product packaging.

Loyal has 20,000 square meters of food machining workshops, CNC machine tools, CNC cutting machines, bending machines, automatic laser welding machines, a full set of sheet metal processing machinery and equipment, 5 hydraulic bending machines, 3 hydraulic shearing machines, and 10T cranes. 2 sets, 9 sets of 16T ~ 100T punching machines, automatic plate rolling machine, welding equipment such as electric welding, argon arc welding, automatic gas shielded welding and other welding equipment, with strong manufacturing and processing capabilities.

Loyal brand was famous well-known at global and domestic market,Loyal have Quality Management system---ISO 9001,Technology Development system ISO 9001,SGS certificate, CE certificates ,SGS and 40 patents on Technology Patent

LOYAL Company Profile

Related News

| Pakistan Customer Instant Noodle Production Line Case |

| Instant Noodle Production Lines Are Becoming More And More Popular |

Product Categories

- Macaroni Production Machine

- Instant Noodle Machine

- Biscuit Making Machine

- Nutrition Bar Manufacturing Equipment

- Bread Crumb Machine

- Food Extruder Machine

- Corn Flakes Production Line

- Corn Puff Snacks Production Line

- Nutritional Baby Rice Powder Food Machine

- Dog Food Manufacturing Equipment

- Feed Production Line

- Cold Pressed Pet Food Machine

- Soya Nuggets Extruder

- Artificial Rice Production Line

- Doritos chips making machine

- Pellet Snack Making Machine

- Modified Starch Machine

- Kurkure Manufacturing Machine

- Industrial Microwave Oven

- Fried Dough Extruder Machine

- Industrial Deep Fat Fryer

- Wafer Line

- Automatic Packaging Machine

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13256674591

- Email[email protected]

- WhatsApp+86 13256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressShandong Xinde Hongyang Industrial Area, Jinan City, Shandong Province, China.

150-200kg/h Industrial Macaroni Pasta Production Line With 304 Stainless Steel

150-200kg/h Industrial Macaroni Pasta Production Line With 304 Stainless Steel Dry pasta production line

Dry pasta production line Industrial Automatic Macaroni Pasta Machine

Industrial Automatic Macaroni Pasta Machine