- Shandong Loyal Industrial Co.,Ltd.

- Industrial Microwave Oven Food Extruder Machine Biscuit Making Machine

Home> Processing> Introduction Of Twin Screw Corn Extruder

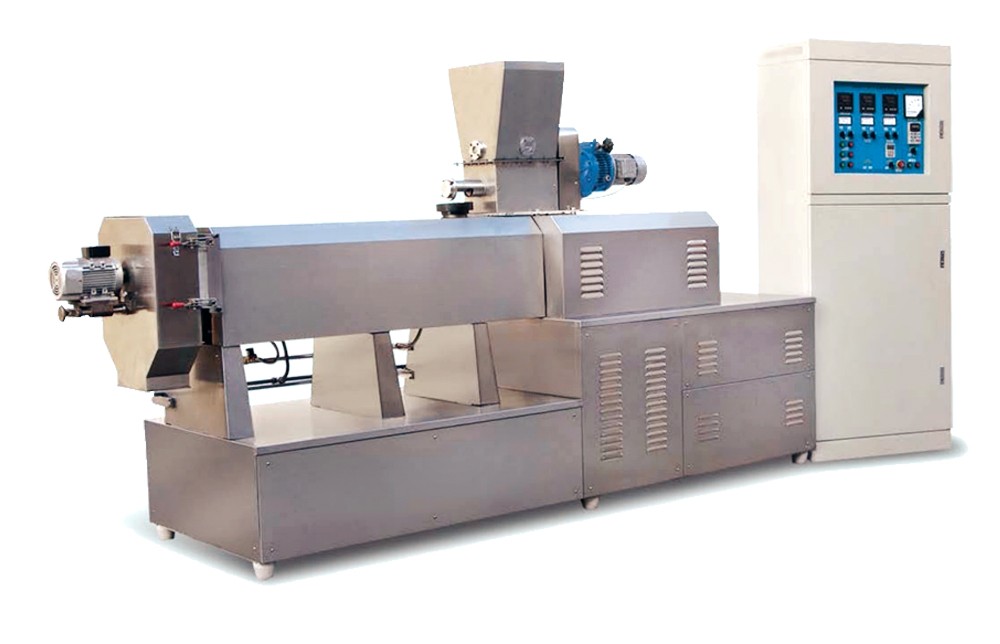

Introduction Of Twin Screw Corn Extruder

2021-01-05 15:36:47Puffed rice flour is a high-quality energy feed specially designed for young animals. Compared with other grain starch granules, rice starch granules are smaller and uniform, and are easy to digest and absorb.

Puffed rice flour is to fully stir the raw materials such as rice and corn flour with a flour mixer, then pour the raw materials into the feeding port of the puffing machine, apply high temperature and high pressure, and then decompress, using the expansion characteristics of the rice itself and the instantaneous moisture inside. Evaporation (flashing) is a processing technology that changes the structure and physical and chemical properties of rice. Raw material expansion is basically to provide sterilized and matured feed for the animal body, thereby reducing the risk of disease of the animal body, and at the same time improving the production performance of the animal body.

The high temperature, high pressure and high shear force produced by the expansion make the starch granules expand and refine, the starch molecular connections are opened, the surface area of the chyme granules is increased, the digestibility is improved, the starch is easier to digest and absorb, and the protein peptide chain is cracked into peptides. , Which greatly improves the protein absorption rate.

It can also replace raw materials to produce puffed rice flour. Puffed rice flour is a high-quality energy feed specially designed for young animals. Compared with other grain starch granules, rice starch granules are smaller and uniform, and are easy to digest and absorb. The spatial structure of rice starch changes during the puffing process, and the starch gelatinization and digestion and absorption rate are improved. The protein contained in rice is of high nutritional quality. Used in piglets, it can reduce the amount of other protein materials and reduce diarrhea caused by resistant protein.

Salmonella, E. coli and other harmful bacteria are all destroyed, thereby reducing the incidence of livestock and poultry. At the same time, the digestibility is over 90%, which relieves diarrhea caused by resistance factors. Its palatability is good, and the puffed product has a unique flavor, which improves feed intake. It has a high degree of gelatinization and forms a gel after heating and tempering, which improves the particle yield, makes the particle structure compact, reduces the powdering rate, and improves the particle quality. It can significantly improve the floating and sinking performance of aquatic feeds, and the loss of water-soluble nutrients from the previous month. It is one of the necessary raw materials for aquatic feeds and special livestock and poultry. Crude protein ≥8.5%; moisture ≤10.0%; fat ≥2.0%; ash content ≤3.0%; crude fiber: ≤3.0%; 0.2-0.5% of total phosphorus; expanded corn has loose and porous, uniform structure, soft texture, starch paste The highlight of the improvement of chemical degree not only has a better color, aroma and taste, but also improves the nutritional value and digestibility.

Salmonella, E. coli and other harmful bacteria are all destroyed, thereby reducing the incidence of livestock and poultry. At the same time, the digestibility is over 90%, which relieves diarrhea caused by resistance factors. Its palatability is good, and the puffed product has a unique flavor, which improves feed intake. It has a high degree of gelatinization and forms a gel after heating and tempering, which improves the particle yield, makes the particle structure compact, reduces the powdering rate, and improves the particle quality. It can significantly improve the floating and sinking performance of aquatic feeds, and the loss of water-soluble nutrients from the previous month. It is one of the necessary raw materials for aquatic feeds and special livestock and poultry. Crude protein ≥8.5%; moisture ≤10.0%; fat ≥2.0%; ash content ≤3.0%; crude fiber: ≤3.0%; 0.2-0.5% of total phosphorus; expanded corn has loose and porous, uniform structure, soft texture, starch paste The highlight of the improvement of chemical degree not only has a better color, aroma and taste, but also improves the nutritional value and digestibility.

Significantly improve the growth performance of weaned piglets. Adding expanded corn can increase the daily gain and daily feed intake of the first weaned piglets by 8% and 6.93%, but the effect is not obvious after 40 days of age. Compared with the normal corn control group, the average daily weight gain of each group from 0 to 14 days was significantly increased (0%, 40%, and more than half). The average daily weight gain of a large part of the extruded corn group was higher between 0-14 days and 0-28 days; compared with the control group, the feed-to-weight ratio of each extruded corn group decreased significantly from 0~0-14 days, but not the same The difference between the addition amount is not significant. All in all, when the added amount of expanded corn is a large part, the growth performance of piglets is good. The high temperature, high pressure and high shear force of the puffed product make the starch granules expand and gelatinize, the starch molecular chain is opened, the surface area of the chylo granules is increased, and the digestibility is greatly improved. At the same time, the peptide chains of the protein split into peptides and amino acids, and the absorption rate of the protein is greatly improved. Corn also has a special flavor.

To be honest, this is the same misunderstanding. The so-called wet method refers to steam pretreatment and then expansion, while the dry method is direct expansion without steam pretreatment. Even if water is added, it is a dry method. Normally, wet manufacturing has a higher power level than dry R&D, but it requires a steam boiler and the investment is larger than dry manufacturing. The production of expanded corn is dry and wet depending on the customer’s specific conditions and product requirements. The digestion of young animals, especially the initially weaned piglets, is immature and has low digestive enzyme activity. Studies have shown that the secretion of amylase in piglets is less than 42 days after birth, and the growth of digestive enzyme activity has been degraded due to weaning stress, which often leads to diarrhea caused by starch and affects manufacturing performance. When the corn is puffed, the starch is gelatinized, and the crystal structure of the starch is irreversibly destroyed. It absorbs water and swells quickly in the small intestine of animals, greatly increasing the functional area and penetration ability of amylase, and improving the hydrolysis speed and digestibility of starch.

Corn Puff Snacks Making Machine

Corn Puff Snacks Making Machine Core Filling Snack Production Line

Core Filling Snack Production Line Puffing Snacks Cereal Making Machine

Puffing Snacks Cereal Making Machine Japanese panko bread crumbs making machine

Japanese panko bread crumbs making machine Japanese Bread Crumbs Processing Line

Japanese Bread Crumbs Processing Line Commercial Japanese Panko Bread Crumb Grinder Machine

Commercial Japanese Panko Bread Crumb Grinder Machine Instant Pasta Production Line

Instant Pasta Production Line